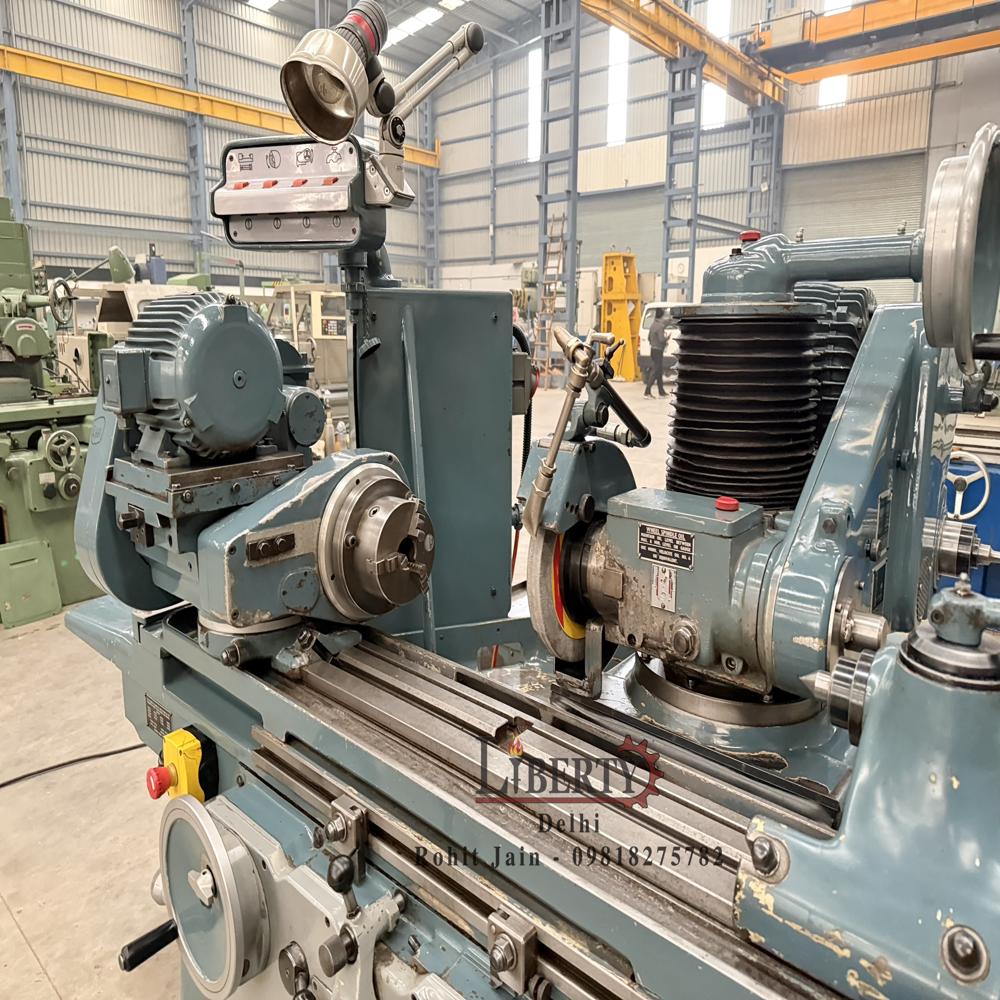

Jones & Shipman 1300 Type EIUR Universal Cylindrical Grinder Machine

Price 100000.0 INR/ Piece

Jones & Shipman 1300 Type EIUR Universal Cylindrical Grinder Machine Specification

- Product Type

- Precision Universal Cylindrical Grinding Machine made by Jones & Shipman (England) in excellent working condition. The model of the machine is 1300 Type EIUR and it is designed for external precision grinding of all kinds, and fitted with a rising and falling swivelling wheel-head for handling all types of tool and cutter grinding operations. The wheel spindle carries an external grinding wheel for cylindrical grinding and a cup or saucer wheel for tool and cutter grinding. Internal grinding is provided by swivelling the wheel-head through 180 degrees. The machine is complete with a 3-point steady, 2-point steady, wheel dresser, coolant tank and pump, and many other accessories. The technical details are as follows -

- General Use

- External and internal cylindrical grinding operations, tool and cutter grinding.

- Material

- Heavy-duty cast iron main frame with hardened and ground spindle components.

- Type

- Universal Cylindrical Grinder

- Capacity

- Between Centers: 585 mm; Swing Over Bed: 255 mm

- Weight (kg)

- Approx. 2000 kg

- Computerized

- No

- Automatic

- Manual operation

- Control System

- Standard manual controls

- Drive Type

- Electric

- Grinding Diameter

- Max. 255 mm

- Grinding Length

- 585 mm

- Spindle Speed

- 14 to 550 rpm (workhead variable speed)

- Grinding Wheel Size

- 355 mm diameter x 38 mm width x 127 mm bore

- Voltage

- 415 V, 3 Phase

- Dimension (L*W*H)

- 2350 mm x 1600 mm x 1540 mm

- Feature

- Rising-and-falling swiveling wheel-head, internal and external grinding applications, accessorized with steadies, coolant system, wheel dresser.

- Color

- Standard machine grey

- Tailstock

- Adjustable with fine adjustment for taper grinding

- Max Swing Over Table

- 255 mm

- Wheel-Head Swivel

- ±90° for external grinding, 180° for internal grinding

- Table Swivel

- ± 7°

- Accessories Included

- 3-point steady, 2-point steady, wheel dresser, coolant tank and pump, comprehensive set of standard accessories

- Max Distance Between Centers

- 585 mm

- Workhead Taper

- Morse Taper No. 4

- Coolant System

- Integral with pump and tank

- Grinding Wheel Peripheral Speed

- Up to 45 m/s

About Jones & Shipman 1300 Type EIUR Universal Cylindrical Grinder Machine

Reliable Performance and Versatility

The Jones & Shipman 1300 Type EIUR is engineered for both external and internal cylindrical grinding tasks. Its swiveling wheel-head and variable workhead speed provide flexibility, while a comprehensive accessory set broadens its capabilities for diverse industrial applications.

Precision Engineering for Superior Results

Featuring a heavy-duty cast iron main frame and hardened, ground spindle components, this grinder ensures stability and accuracy. Fine adjustment on the tailstock facilitates precise taper grinding, and the manual controls offer operators full command over the grinding process.

Integrated Coolant and Accessory System

The machine includes an integral coolant tank with pump to support efficient grinding operations. Accessories such as steadies and a wheel dresser further optimize performance, promoting long grinding wheel life and consistent results.

FAQ's of Jones & Shipman 1300 Type EIUR Universal Cylindrical Grinder Machine:

Q: How does the Jones & Shipman 1300 Type EIUR facilitate both external and internal grinding?

A: The 1300 Type EIUR features a swiveling wheel-head that can be set to 90 for external grinding and up to 180 for internal grinding. This design allows operators to seamlessly shift between different grinding applications.Q: What is the maximum workpiece size the machine can handle?

A: The machine accommodates pieces up to 585 mm in length between centers and provides a maximum swing over the bed of 255 mm, making it suitable for medium-sized components.Q: When is taper grinding achievable with this machine?

A: Taper grinding can be performed by leveraging the adjustable and fine-tuning tailstock, combined with the table's 7 swivel range, enabling precise tapers during operation.Q: Where is the coolant system located, and how does it function?

A: The grinder comes with an integral coolant tank and pump, ensuring adequate cooling of the grinding wheel and workpiece directly at the grinding area for improved finish and extended wheel life.Q: What components are included with the machine upon delivery?

A: Standard accessories supplied include a 3-point steady, 2-point steady, wheel dresser, coolant tank and pump, and a comprehensive set of standard tools and fixtures.Q: How is workpiece precision maintained during grinding?

A: Precision is achieved through a combination of a robust cast iron main frame, variable-speed workhead (14-550 rpm), and fine-adjustment tailstock for taper workloads, alongside hardened and ground spindle components.Q: What are the main benefits of using this cylindrical grinder in an industrial setting?

A: Operators benefit from its versatility for internal and external grinding, high accuracy, reliable performance, and a complete accessory package, making it a valuable asset for manufacturers, tool rooms, and repair shops.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cylindrical Grinder Category

Fortuna 400 mm Length Automatic Cylindrical Grinding Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

General Use : Industrial Cylindrical Grinding

Drive Type : Electric

Computerized : No

Product Type : Automatic Cylindrical Grinding Machine

TOS BUA 31/1000 Cylindrical Grinder

Price 8950 INR / Piece

Minimum Order Quantity : 1 Piece

General Use : Grinding cylindrical surfaces

Drive Type : Other, Hydraulic

Computerized : No

Product Type : Cylindrical Grinder

Fortuna Germany Angular Cylindrical Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

General Use : Precise Surface and Cylindrical Grinding

Drive Type : Other, Belt Driven

Computerized : No

Product Type : Angular Cylindrical Grinder

Grisetti Universal Cylindrical Grinder

Price 5500 INR / Piece

Minimum Order Quantity : 1 Piece

General Use : Metal Grinding

Drive Type : Electric

Computerized : Yes

Product Type : Machine Tool

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry