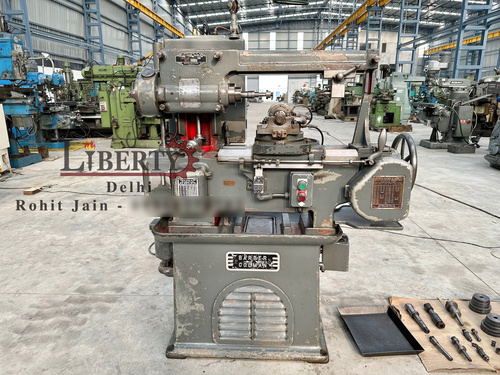

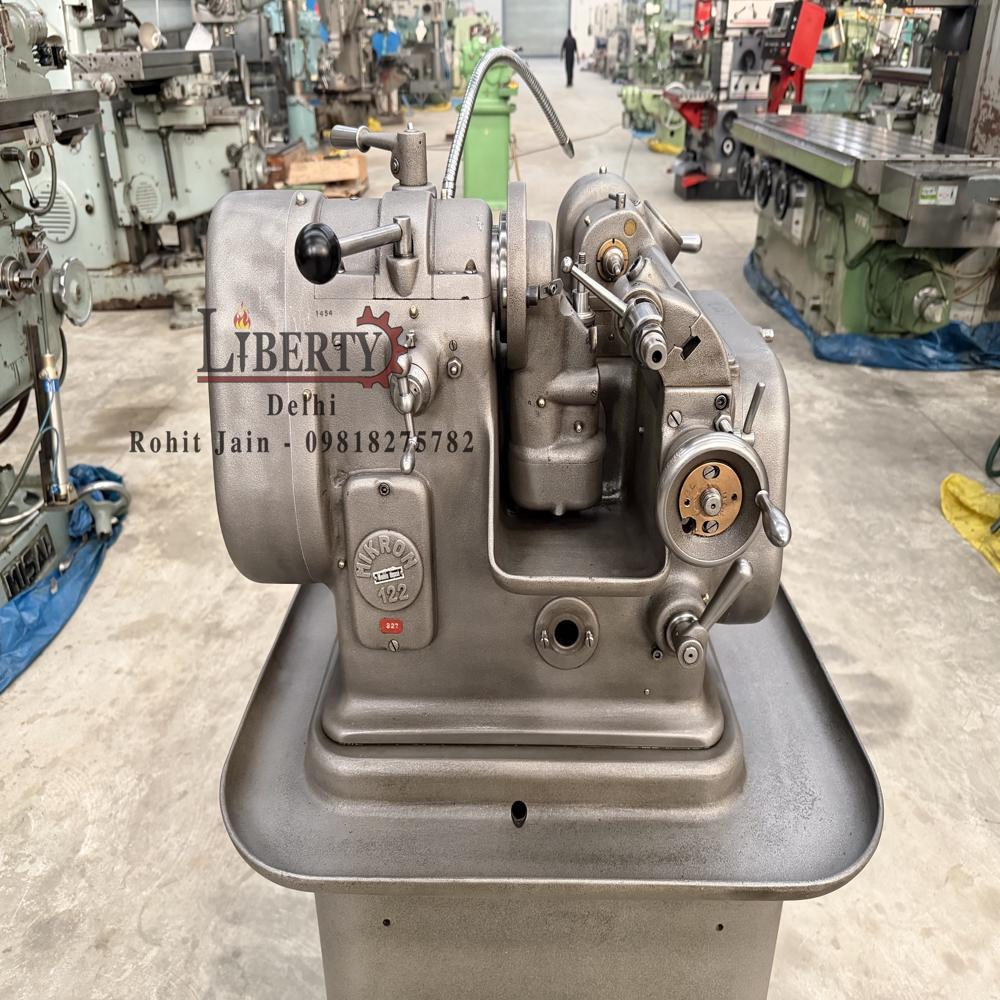

Mikron Switzerland Type 122 Precision Horizontal Gear Hobbing Machine

Price 100000.0 INR/ Piece

Mikron Switzerland Type 122 Precision Horizontal Gear Hobbing Machine Specification

- Color

- Standard machine grey

- Feature

- Complete with change gears, operating manuals, electrical drawings, spare spindle, and additional accessories

- Machine Type

- Mikron (Switzerland) make High-Precision Horizontal Gear Hobbing Machine in excellent condition. The model of the machine is Type 122 and it is complete with Change Gears, Operating Manuals, Electrical Drawings, spare Spindle & many other accessories. The technical details are as follows -

- Used For

- High-precision horizontal gear hobbing operations

- Condition

- Excellent

- Power

- 2.0 kW

- Voltage

- 415 V / 3 Phase

- Output

- Precision hobbed gears

- Maximum Gear Width

- 60 mm

- Spindle Bore

- 22 mm

- Maximum Workpiece Diameter

- 125 mm

- Table Bore

- 28 mm

- Hob Speed Range

- 70 to 560 rpm

- Module Range

- 0.5 to 3 module

- Centre Distance (hob and workpiece)

- 10 mm to 90 mm

- Accessories Included

- Change gears, spare spindle, operating manuals, electrical diagrams, and various extras

- Feed Range

- 0.02 to 3 mm/rev

About Mikron Switzerland Type 122 Precision Horizontal Gear Hobbing Machine

Superior Engineering and Precision

With precise centre distance adjustment from 10 mm to 90 mm, the Mikron Type 122 enables accurate gear manufacturing for diverse industrial needs. Its horizontal layout and robust construction guarantee consistent, high-quality results while handling various gear profiles and sizes.

Fully Equipped for Immediate Operation

Supplied with change gears, a spare spindle, operating manuals, and electrical diagrams, this gear hobbing machine is turnkey-ready. Users benefit from straightforward setup and minimal downtime, thanks to the inclusion of essential accessories and documentation.

Energy-Efficient and Safe Design

The 2.0 kW power rating and 415 V/3 phase electrical system ensure reliable performance with operational safety. The supplied electrical diagrams and manuals provide clear guidance for installation and maintenance, meeting stringent industrial safety standards.

FAQ's of Mikron Switzerland Type 122 Precision Horizontal Gear Hobbing Machine:

Q: How is the Mikron Type 122 precision horizontal gear hobbing machine used for gear manufacturing?

A: The Mikron Type 122 cuts gears by rotating the workpiece and hob in precise synchronization, generating accurate tooth profiles suitable for high-precision industrial applications.Q: What is the maximum size of gear that can be hobbed on this machine?

A: This hobbing machine accommodates workpieces up to 125 mm in diameter and gear widths of up to 60 mm, covering a broad range of gear sizes common in manufacturing.Q: When should I use the supplied change gears and spare spindle?

A: Change gears are used to adjust the gear-cutting ratios for different gear specifications, while the spare spindle is available for quick replacement, ensuring minimal downtime during maintenance or adjustments.Q: Where are the operational manuals and electrical diagrams stored with the machine?

A: Operational manuals and electrical diagrams are included with each machine shipment and typically stored in a dedicated compartment for easy access during setup or troubleshooting.Q: What is the process for setting up and starting the Mikron Type 122 gear hobbing machine?

A: Setup involves mounting the correct change gears, configuring centre distance and speeds, securing the workpiece, and following the provided manuals and diagrams for precise calibration before operation.Q: How does the module range benefit the gear manufacturing process?

A: A module range from 0.5 to 3 allows the production of various gear sizes and types. This flexibility ensures compatibility with numerous industrial gear requirements, broadening the machine's application scope.Q: What advantages does this machine offer to exporters, manufacturers, and traders in India?

A: Its excellent condition, comprehensive accessories, and reliability support higher productivity, reduced maintenance, and versatile gear production, making it a valuable asset for industrial businesses in the Indian market.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Hobbing Machine Category

TOS FO-6 Gear Hobbing Machine

Price 8900 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Machine Type : Gear Hobbing Machine

Condition : Used Good condition

Feature : Precision gear cutting with semiautomatic controls

Color : Green

Stanko USSR 2.5 Module Gear Hobbing Machine

Price 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Machine Type : Gear Hobbing Machine

Condition : Used

Feature : SemiAutomatic, Robust Cast Iron Frame, Precision Adjustment

Color : Industrial Green

TOS (Czech) FO-16 Gear Hobbing Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Machine Type : Gear Hobbing Machine

Condition : Used

Feature : Heavy duty, high precision, reliable performance

Color : Blue / Grey

Barber Colman 6-10 Horizontal Gear Hobbing Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Machine Type : Horizontal Gear Hobbing Machine

Condition : Used

Feature : Robust construction, precision machining capability

Color : Industrial Green

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry