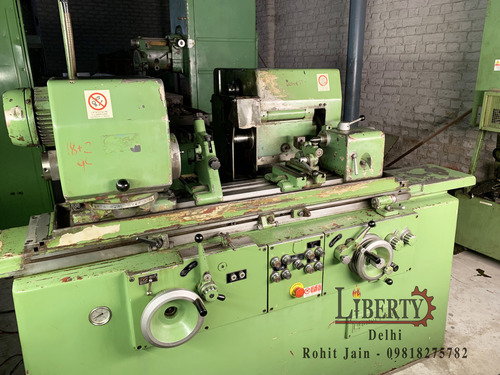

Olivetti R5 Cylindrical Grinder

Olivetti R5 Cylindrical Grinder Specification

- Product Type

- Industrial Cylindrical Grinder

- General Use

- Precision external and internal grinding of cylindrical components

- Material

- Cast Iron, Steel

- Type

- Universal Cylindrical Grinding Machine

- Capacity

- Standard (Refer to specific model for exact figure)

- Weight (kg)

- Approx. 1600 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- Control System

- Manual/Mechanical

- Drive Type

- Electric

- Grinding Diameter

- Max 200 mm

- Grinding Length

- Max 1000 mm

- Spindle Speed

- Up to 1800 rpm

- Grinding Wheel Size

- 400 mm x 50 mm x 203 mm

- Voltage

- 380V / 3 Phase

- Dimension (L*W*H)

- 2200 mm x 1600 mm x 1400 mm

- Feature

- Hardened bed, High precision spindle bearings, Adjustable tailstock

- Color

- Olive green

- Coolant System

- Integrated

- Table Swivel

- ±8°

- Lubrication System

- Auto lubrication

- Wheelhead Swivel

- ±30°

- Phase

- Three Phase

- Tailstock Quill Travel

- 60 mm

- Grinding Accuracy

- ±0.002 mm

- Chuck Size

- 160 mm

- Surface Finish

- Ra 0.2 µm

- Max Workpiece Weight

- 80 kg

- Main Motor Power

- 3.7 kW

About Olivetti R5 Cylindrical Grinder

Make - Olivetti (Italy)

- Model - R5

- Center Height - 150 mm

- Max. Diameter of Job - 300 mm

- Length of Job - 600 mm

- Grinding Wheel Diameter - 350 mm

- Grinding Wheel Width - 50 mm

- With Internal Grinding Attachment.

- With Hydraulic Rapid Movement of Wheel-Head.

- Equipped with steady, dresser, coolant tank & pump.

- Automatic Depth Adjustment "Auto-Cut"

- Swivel-type Wheel Head.

- Complete with spare wheels, flange, balancing mandle, job carrier.

- Machine is in excellent working condition.

Precision and Performance

Built for accurate cylindrical grinding, the Olivetti R5 provides enhanced spindle stability and consistent results, ensuring an outstanding surface finish. Its auto-lubrication and integrated coolant systems maintain optimal operating conditions, which translates to reliable production with minimal downtime.

Versatility for Multiple Applications

The R5 accommodates varied component sizes, offering a table swivel of 8 and a wheelhead swivel of 30. Its universal design supports both external and internal grinding applications, making it suitable for workshops, manufacturers, or suppliers handling diverse cylindrical components.

Durability and Maintenance

Featuring a hardened bed and high-precision spindle bearings, this cylindrical grinder is engineered for longevity. The integrated auto-lubrication system further reduces manual intervention, extends component life, and ensures smooth machine operation even under heavy loads.

FAQs of Olivetti R5 Cylindrical Grinder:

Q: How does the integrated coolant system benefit the grinding process on the Olivetti R5?

A: The integrated coolant system helps regulate the temperature during grinding, preventing overheating and thermal deformation of both the workpiece and grinding wheel. This results in improved surface finish, extended tool life, and more consistent high-precision output.Q: What materials can be processed with the Olivetti R5 Cylindrical Grinder?

A: The machine is optimized for grinding a range of cylindrical components manufactured from materials like cast iron and steel. Its robust construction allows for reliable performance on hard and high-tolerance materials.Q: When should the auto-lubrication system be checked or maintained?

A: While the auto-lubrication system minimizes the need for frequent manual checks, its recommended to inspect the system periodically as per the manufacturers maintenance guidelines or whenever irregular machine operation or increased friction is noticed.Q: Where is the Olivetti R5 best utilized?

A: This cylindrical grinder is well-suited for machine shops, manufacturing plants, and supplier facilities requiring high-precision external and internal cylindrical grinding for components used in engineering, automotive, or industrial applications.Q: What is the typical process for setting up a part on this cylindrical grinder?

A: Users adjust the table and wheelhead to the required angles, secure the part using the 160 mm chuck or adjustable tailstock, select the appropriate spindle speed (up to 1800 rpm), and set grinding parameters manually through the mechanical control system before initiating the grinding operation.Q: How does the grinder maintain high surface finish and precision?

A: The combination of a hardened bed, high-precision spindle bearings, and a stable mechanical drive ensures minimal vibration and excellent alignment, achieving surface finishes as fine as Ra 0.2 m and dimensional accuracy within 0.002 mm.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cylindrical Grinder Category

Kellenberger 1000U High Precision Cylindrical Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Other, CNC

General Use : Industrial use for precision grinding of cylindrical components

Grinding Wheel Size : 500 mm x 80 mm

Automatic : Yes

Kellenberger 600 RJ Universal Cylindrical Grinder

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Other, Manual, with electrical panel

General Use : Precision external and internal cylindrical grinding

Grinding Wheel Size : 400 mm x 50 mm x 127 mm

Automatic : No

Ajax England Universal Cylindrical Grinder Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Other, Manual lever and wheel operation

General Use : Precision external and internal grinding of cylindrical and conical parts

Grinding Wheel Size : 350 mm x 40 mm x 127 mm

Automatic : No

Jones Shipman 1310 Cylindrical Grinding Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Manual

General Use : Precision external and internal grinding

Grinding Wheel Size : Max 355 mm Diameter x 38 mm Width

Automatic : No

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry