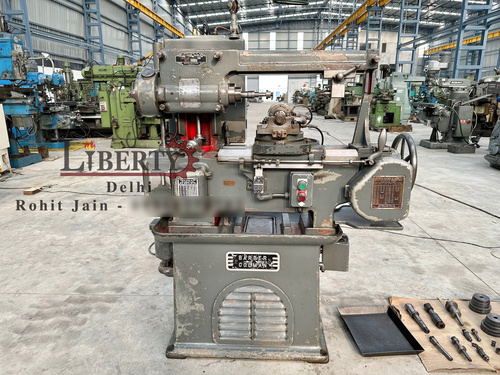

Pfauter P-1250 Hydraulic Gear Hobbing Machine

Price 100000.0 INR/ Piece

Pfauter P-1250 Hydraulic Gear Hobbing Machine Specification

- Machine Type

- Pfauter (Germany) make High-Production Hydraulic Gear Hobbing Machine in excellent working condition. The model of the machine is P-1250 and the Maximum Module Capacity is 12 Modules and Maximum Gear Diameter is 1250 mm. It is a Heavy-Duty, High-Speed, complete Auto-Cycle type Gear Hobbing Machine. The machine is capable of Radial Hobbing, Axial Hobbing, Tangential Hobbing, Radial-Axial Hobbing, Radial-Tangential, etc. The machine also has a Sliding type Support Column so it is not necessary to take off the support column even for larger diameter jobs. It is also equipped with a Hydraulically operated swivell-able tail-stock. The machine is capable of complete Auto-Cycle working and it can also be used in manual mode. The machine is complete with its Change Gears, Mandrels, many different types & sizes of Job Supports, Operating Manual, Coolant Tank and Pump, Leveling Pads, Covers, Splash Guards , Chip Conveyor, and many other accessories. The technical details are as follows -

About Pfauter P-1250 Hydraulic Gear Hobbing Machine

Make - Pfauter (Germany)Model - P-1250

Max. Module - 12 modules

Max. Diameter of the Gear - 1250 mm

Max. Vertical Travel of Hob-Slide - 590 mm

Table Diameter - 950 mm

Max. Hob Cutter Size - Diameter 220 mm x 260 mm Length

Max. Hob Shifting - 240 mm

Table Bore Diameter - 200 mm

Hob Cutter Speeds - 32 rpm to 200 rpm

Min. Distance between Center of Hob & Work-Piece - 60 mm

Max. Distance between Center of Hob & Work-Piece - 740 mm

Max. Diameter of Gear with Tail-Stock - 850 mm

Weight of the Machine - 15.5 tons (Approximately)

- It is a High-Production Auto-Cycle type Heavy Duty Gear Hobbing Machine.

- Continuously variable Hob Rotation Speeds & Feed Rates of Travels.

- Complete with Change Gears, Mandrels, Job Supports, Leveling Pads etc.

- Complete with Covers & Splash Guards, Coolant Tank, Pump & many other accessories.

- Operating Manual of the machine is available.

- Machine is in excellent working condition.

High-Production Efficiency

With the Pfauter P-1250, manufacturers can boost productivity thanks to its fully automatic cycle capabilities and heavy-duty construction. This gear hobbing machine is engineered to handle continuous, high-speed operations, ideal for large-scale gear production. Its comprehensive automation options streamline workflows while supporting consistent, high-quality results.

Versatile Gear Machining Capability

Designed for adaptability, the P-1250 can perform radial, axial, tangential, and combined hobbing operations. Its hydraulic features, sliding support column, and swivell-able tailstock offer the flexibility needed for complex and large-diameter jobs. This makes the machine suitable for a wide variety of gear types and cutting techniques.

Comprehensive Accessory Package

The P-1250 is delivered with an extensive range of accessories, including change gears, mandrels, diverse job supports, operating manual, coolant tank, pump, leveling pads, covers, splash guards, and chip conveyor. This robust setup ensures users are fully equipped for immediate and efficient operation, enhancing convenience and safety.

FAQ's of Pfauter P-1250 Hydraulic Gear Hobbing Machine:

Q: How does the Pfauter P-1250 hydraulic gear hobbing machine benefit production efficiency?

A: The P-1250 is built for high-speed, high-volume gear cutting. Its complete auto-cycle operation minimizes manual intervention and offers consistent quality, making it highly suitable for mass production demands within industries such as manufacturing, exporting, and trading.Q: What types of hobbing processes can be performed on this machine?

A: The machine supports radial, axial, tangential, radial-axial, and radial-tangential hobbing. This versatility allows users to manufacture a wide range of gear profiles and sizes to meet diverse application requirements.Q: When is it recommended to use the sliding support column feature?

A: The sliding support column is essential when machining larger diameter gears, as it allows support without the need to dismantle the column, ensuring stability and ease of operation while accommodating oversized workpieces.Q: Where can the Pfauter P-1250 be installed and operated?

A: This machine is suitable for industrial environments such as manufacturing plants, export/import workshops, and supplier facilities across India. Its heavy-duty structure requires proper leveling pads and robust foundation for optimal operation.Q: What accessories and tools come standard with this hobbing machine?

A: The P-1250 is delivered complete with change gears, mandrels, various job supports, an operating manual, coolant system, chip conveyor, leveling pads, splash guards, and more. These components ensure the machine is ready for immediate use and easy maintenance.Q: How can users switch between automatic and manual modes on the P-1250?

A: Operators can select between complete auto-cycle mode for continuous production or manual mode for customized, supervised machining using the machine's control interface, offering flexibility in operational approaches depending on production needs.Q: What is the process for setting up the machine for different gear sizes?

A: To accommodate different gear sizes, operators adjust the support column and tailstock as needed, utilize the appropriate change gears and mandrels, and follow the setup procedures outlined in the provided operating manual. The machine's design streamlines changeovers and supports a wide range of job fixtures.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Hobbing Machine Category

TOS FO6 Gear Hobbing Machine

Price 1100 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Color : Green

Machine Type : Gear Hobbing Machine

Feature : Robust design capable of precision gear cutting

Used For : Gear manufacturing

Donini A29 Gear Hobbing Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Blue/Gray

Machine Type : Gear Hobbing Machine

Feature : High Precision, Robust Construction, Automatic Feed

Used For : Gear Cutting

Barber Colman 6-10 Horizontal Gear Hobbing Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Industrial Green

Machine Type : Horizontal Gear Hobbing Machine

Feature : Robust construction, precision machining capability

Used For : Gear manufacturing cutting various gear types

Pfauter P630 Hydraulic Gear Hobbing Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Standard industrial green

Machine Type : Hydraulic Gear Hobbing Machine

Feature : High precision; Hydraulic control; Robust construction

Used For : Gear cutting and hobbing operations

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry