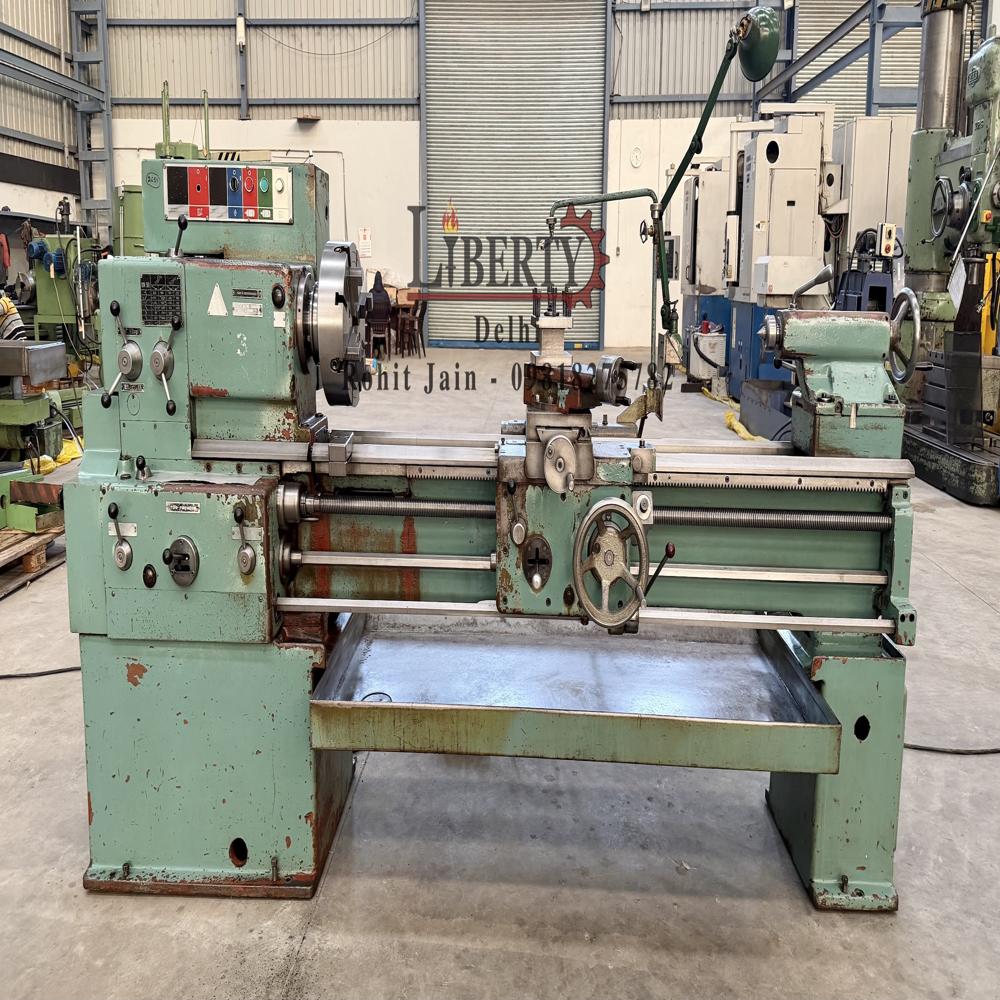

Ramo Precision Lathe Machine

Price 3500 USD ($)/ Piece

Ramo Precision Lathe Machine Specification

- Product Type

- Precision Lathe Machine

- Material

- Cast Iron

- Cutting Thickness

- Up to 10 mm

- Cutting Speed

- 40-2000 RPM

- Engraving Area

- 500 mm

- CNC Or Not

- No, Manual

- Automatic Grade

- Semi-Automatic

- Control System

- Manual Gear Control

- Max. Swing Diameter

- 400 mm

- Voltage

- 415 V

- Weight (kg)

- 1200 kg

- Dimension (L*W*H)

- 2100 x 950 x 1600 mm

- Capacity

- High Precision Metalworking

- Feature

- Robust Construction, High Accuracy, Low Vibration

- Color

- Blue & White

- Bed Type

- Heavy Duty, Induction Hardened

- Spindle Bore

- 52 mm

- Chuck Size

- 200 mm

- Number of Spindle Speeds

- 8

- Usage

- Industrial Turning Operations

- Lubrication System

- Automatic

- Main Motor Power

- 2.2 kW

- Surface Finish Quality

- Ra 1.6 µm

- Coolant System

- Yes

- Distance Between Centers

- 1000 mm

- Tailstock Travel

- 120 mm

About Ramo Precision Lathe Machine

Make - Ramo (France)

Model - T44

Center Height - 220 mm

Length of Job - 650 mm

Max. Job Dia. over Bed - 440 mm

Max. Job Dia. over Cross-Slide - 220 mm

Bed Width - 335 mm

Chuck Diameter - 200 mm

Spindle Speeds - 45 rpm to 1600 rpm

Spindle Bore - 40 mm

- Equipped with 2-Axis DRO

- Complete with accessories like tool holders, etc.

- Machine is in excellent working condition.

Video Link - https://youtu.be/oFsh6CVPMAg

Engineered for High Precision Metalworking

This Ramo Precision Lathe Machine is built to meet the highest standards for industrial turning. Its induction-hardened bed and cast iron construction minimize wear and deformation, prolonging the machines operational life. The 52 mm spindle bore and 200 mm chuck allow for varied component sizes, while low vibration mechanisms ensure consistently accurate machining.

Advanced Features for Seamless Operation

Equipped with a semi-automatic grade, this lathe offers both manual control and modern conveniences like automatic lubrication and a reliable coolant system. Eight spindle speeds, an efficient 2.2 kW motor, and a generous tailstock travel of 120 mm make it suitable for a wide range of applications, guaranteeing adaptability and ease of use in busy workshops.

Performance, Reliability, and Versatility

Supporting up to 10 mm cutting thickness and a swing diameter of 400 mm, the Ramo Precision Lathe Machine supports versatile machining operations. Its compact footprint (2100 x 950 x 1600 mm) and striking blue and white design suit contemporary factory settings, while its 1200 kg weight ensures high stability during operation. High precision and quality fitments mean minimized downtime and enhanced productivity.

FAQs of Ramo Precision Lathe Machine:

Q: How does the induction-hardened bed benefit the Ramo Precision Lathe Machines performance?

A: The induction-hardened bed significantly increases hardness and wear resistance, ensuring prolonged precision and minimal deformation during continuous heavy-duty use. This results in consistent accuracy and reduced maintenance over the machines operational life.Q: What types of operations can be performed with this lathe machine?

A: This lathe is ideal for high precision industrial turning operations, including facing, turning, threading, parting, and engraving on cast iron and other metals. It supports a cutting thickness of up to 10 mm and has an engraving area of 500 mm.Q: When should automatic lubrication and the coolant system be used?

A: Both systems should operate during all machining sessions to minimize friction, prevent overheating, and extend the lifespan of machine components. These features also help achieve the high surface finish quality of Ra 1.6 m.Q: Where is the Ramo Precision Lathe Machine typically used?

A: This machine is widely utilized in industrial setups such as manufacturing plants, metalworking workshops, and toolroomsespecially by exporters, importers, manufacturers, suppliers, and traders looking for reliable manual turning solutions.Q: What process controls does the lathe utilize?

A: This machine operates by manual gear control, providing operators with direct control over spindle speeds (ranging from 40 to 2000 RPM) and other machining parameters for high adaptability on different tasks.Q: How does the robust construction of the lathe improve its usage?

A: The heavy-duty cast iron build and low-vibration design ensure machine stability and accuracy during demanding operations, while the substantial 1200 kg weight and rigid frame help deliver high precision and repeatability in metalworking tasks.Q: What are the key benefits of this lathe compared to CNC alternatives?

A: This lathe offers manual versatility, lower upfront investment, straightforward maintenance, and hands-on control, making it ideal for tasks that require adaptability, rapid set-up, and skilled craftsmanship without the complexity of full CNC automation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lathe Machine Category

TOS SU80A 2900 mm Heavy Duty Lathe Machine

Price 15000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 415 V / 3 Phase / 50 Hz

Color : Standard Industrial Grey / Green

Feature : Other, Heavy Duty, High Precision, Long Bed

CNC Or Not : Other, No (Conventional Lathe)

TOS SU63A / 2750 Heavy Duty Lathe Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 415 V, 50 Hz, 3 Phase

Color : Green

Feature : Other, Hardened and Ground Bed, Heavy Duty Tailstock, Full Length Splash Guard

CNC Or Not : Other, Conventional (Not CNC)

TOS SN-50A Gap Bed Lathe Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 415 V

Color : Sky Blue & White

Feature : Other, Gap Bed, Hardened & Ground Bedways, HeavyDuty Construction, Precision Engineering

CNC Or Not : Other, No, Manual Machine

TOS Czech SN55B Gap Bed Lathe Machine

Price 100000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 415 V, 3 Phase

Color : Standard Industrial Grey

Feature : Other, Includes Follow Rest, Job Steady, Coolant Pump; GapBed Type

CNC Or Not : Other, Not CNC (Manual Lathe)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry