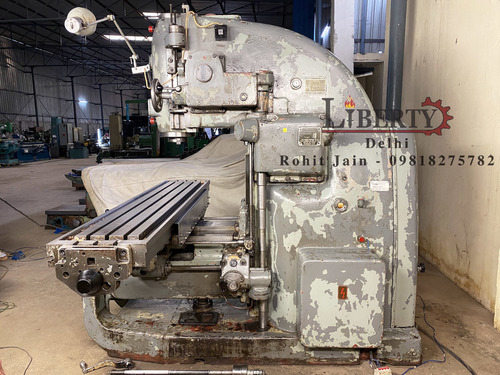

Sachman Italy 2000 x 730 Bed Type Milling Machine

Price 100000 INR/ Piece

Sachman Italy 2000 x 730 Bed Type Milling Machine Specification

- Model

- Sachman Italy 2000 x 730

- Rotation

- Spindle, Manual & Powered

- Product Type

- Bed Type Milling Machine

- General Use

- Industrial Milling

- Material

- High Quality Cast Iron

- Type

- Horizontal Milling

- Capacity

- Heavy Duty

- Weight (kg)

- Approx. 4500 kg

- Computerized

- No

- Automatic

- Manual Operation

- CNC Or Not

- Not CNC

- Control System

- Conventional

- Table Size

- 2000 x 730 mm

- Table Slide Way

- Hardened and Ground

- Floor Space

- Approx. 3500 x 3000 mm

- Spindle Speed

- 30 to 1800 RPM

- Power

- 7.5 kW

- Voltage

- 380V, 3 Phase

- Dimension (L*W*H)

- Approx. 3200 x 2000 x 2100 mm

- Feature

- Rigid Construction, High Precision

- Color

- Standard Industry Green

- Longitudinal Travel (X-axis)

- 2000 mm

- Year of Manufacture

- 1997

- Head Type

- Universal Swivelling Head

- Max. Load on Table

- 2500 kg

- Main Motor

- 7.5 kW

- Vertical Travel (Z-axis)

- 600 mm

- Spindle Taper

- ISO 50

- Coolant System

- Fitted

- Lubrication System

- Automatic Centralized

- Accessories

- Digital Readout, Machine Lamp, Splash Guard

- Cross Travel (Y-axis)

- 730 mm

- Feed Range

- 10 - 1000 mm/min

- Condition

- Used, Good Working Order

Sachman Italy 2000 x 730 Bed Type Milling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About Sachman Italy 2000 x 730 Bed Type Milling Machine

Make - Sachman (Italy)

Table Size - 2000 mm x 730 mm

XYZ Travel - 1750 mm x 800 mm x 725 mm

Spindle Speeds - 30 rpm to 2000 rpm

Spindle Taper - ISO 50

Table Feed Travel Rates - 0 mm/min to 1200 mm/min (Continuously variable)

Spindle Motor - 11 kW

Max. Height between Table to Spindle Nose - 760 mm

- Equipped with Ball-Screws in all the 3-Axis.

- Hydraulic Clamping of the Tool Holder.

- Equipped with Heidenhain make 3-Axis programmable DRO.

- Universal Double-Swivel type Head for Vertical, Horizontal & Angular Milling.

- Machine is in excellent working condition.

Video of The Machine -

High-Performance Bed Type Milling

Experience outstanding industrial milling with the Sachman Italy 2000 x 730. Its combination of a large bed, universal swivelling head, and precise control systems makes it suitable for demanding tasks on various materials. The heavy-duty cast iron structure ensures vibration-free operation even under maximum load. Fitted accessories and an automatic lubrication system optimize productivity and maintenance.

Rugged Construction and Reliability

Engineered with a hardened and ground table slide way and a robust 7.5 kW motor, this machine delivers exceptional rigidity and high-precision results. The automatic centralized lubrication system and fitted coolant setup help prolong machine life, ensuring consistent performance for manufacturers, exporters, and industrial operators. Its proven durability makes it a reliable choice for extended production runs.

FAQ's of Sachman Italy 2000 x 730 Bed Type Milling Machine:

Q: How do you operate the Sachman Italy 2000 x 730 Milling Machine?

A: The Sachman 2000 x 730 operates manually and uses conventional controls, with spindle speeds adjustable from 30 to 1800 RPM. Movement along the X, Y, and Z axes is managed via manual or powered controls, allowing operators to tailor feed rates from 10 to 1000 mm/min for precise industrial milling tasks.Q: What materials and workpieces can this milling machine handle?

A: With a high load capacity of 2500 kg and a rigid cast iron structure, the Sachman bed type milling machine is suitable for heavy-duty industrial components, large metal parts, and machinable materials requiring stability and precision. The universal swivelling head also accommodates complex milling angles and operations.Q: When should maintenance be performed on this used machine?

A: Although equipped with automatic centralized lubrication for ease of maintenance, regular inspection of moving parts, coolant levels, and the lubrication system is recommended. Maintenance should be scheduled according to usage intensity and in line with best practices for used industrial machinery.Q: Where is the Sachman 2000 x 730 typically used?

A: This milling machine is commonly found in industrial workshops, manufacturing facilities, and metalworking plants that demand robust, reliable, and precise milling capabilities. Its large floor space and table dimensions make it ideal for heavy-duty, high-capacity workspaces.Q: What benefits does the universal swivelling head provide?

A: The universal swivelling head greatly increases machining flexibility, enabling the operator to mill at various angles and perform complex operations without repositioning the workpiece. This boosts productivity and allows for greater versatility in production.Q: How does the coolant and lubrication system enhance operations?

A: The fitted coolant system efficiently manages heat during milling, protecting tools and workpieces from thermal damage. The automatic centralized lubrication setup ensures optimal functioning of all vital components, reducing wear and the likelihood of downtime.Q: What makes the Sachman Italy 2000 x 730 a good investment for industrial operations?

A: Despite being used, this machine combines heavy-duty capability, high precision, robust build, and reliable accessories like digital readout and splash guard. Its durability and manual controls make it straightforward to operate, maintain, and integrate into a variety of industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Milling Machine Category

Jotes FYA-41 Heavy Duty Vertical Milling Machine

Price 23500 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : Heavy Duty

Automatic : No

Color : Other, Standard (as per image)

CNC Or Not : Other, No

FIL Italy 2500 mm x 600 mm Bed Milling Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : Heavy Duty

Automatic : No

Color : Other, Blue & White

CNC Or Not : Other, Not CNC

Saimp Italy Vertical Turret Milling Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : Heavy Duty/MediumLarge Batch

Automatic : Other, No (Manual Feed)

Color : Other, Standard Machine Grey with Blue accents

CNC Or Not : Other, Not CNC (Conventional Machine)

Cernotto Italy 1250 mm x 350 mm Vertical Turret Milling Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : Heavy duty

Automatic : No

Color : Other, Industrial grey

CNC Or Not : Other, Not CNC

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry