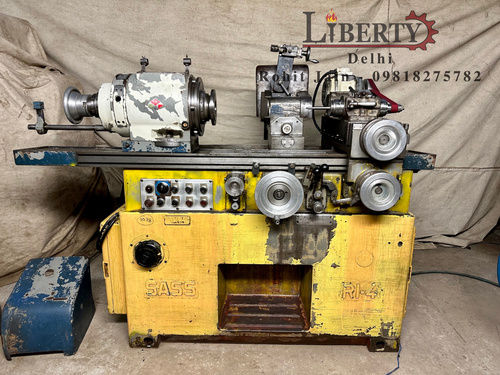

SASS Italy RI-4 Internal Grinder Machine

Price 25000 INR/ Piece

SASS Italy RI-4 Internal Grinder Machine Specification

- Model

- RI-4

- Rotation

- Spindle rotation, manual table rotation

- Product Type

- Internal Grinder Machine

- General Use

- Internal grinding operations for cylindrical and conical bores

- Material

- Cast Iron, Steel Components

- Type

- Precision Grinder

- Capacity

- Up to 50 mm bore diameter

- Weight (kg)

- Approx. 600 kg

- Computerized

- No

- Automatic

- No, manual operation

- CNC Or Not

- Not CNC

- Control System

- Hand-operated/mechanical

- Table Size

- 360 x 90 mm

- Table Slide Way

- V-flat type

- Magnetic Chuck Size

- 100 mm

- Grinding Wheel Size

- 100 x 50 x 20 mm

- Grinding Wheel Speed

- 26,000 rpm

- Grinding Length

- 100 mm

- Floor Space

- 920 x 800 mm

- Fuel Tank Capacity

- 6 Liters

- Spindle Speed

- 13,500 rpm

- Power

- 1.1 kW

- Voltage

- 415V / 3 Phase

- Dimension (L*W*H)

- Approx. 1460 x 1100 x 1500 mm

- Feature

- High accuracy, rigid construction, easy operation

- Color

- Industrial Grey

- Chuck Type

- Magnetic

- Work Table Travel

- 120 mm

- Lubrication

- Centralized manual lubrication system

- Noise Level

- < 75 dB(A)

- Max Swing Over Bed

- 200 mm

- Max Bore Depth

- 100 mm

- Coolant System

- Integral coolant system provided

- Main Motor

- 1.1 kW AC motor

SASS Italy RI-4 Internal Grinder Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About SASS Italy RI-4 Internal Grinder Machine

Make - SASS (Italy)

Model - RI-4

Center Height - 185 mm

Max. Swing Diameter of Job - 370 mm

Max. Table Travel - 260 mm

Spindle Diameter - 80 mm

Work-Head Speeds - 50 rpm to 500 rpm

Work-Head Rotation - +15 degree to -15 degree

Face Grinding Wheel Diameter - 160 mm

- Equipped with Face Grinding Attachment.

- Machine is in excellent working condition.

Video of The Machine -

Reliable Precision Grinding

The RI-4 delivers exceptional precision thanks to its rigid construction and high-quality internal components. Designed for both cylindrical and conical bore grinding, it ensures consistently accurate results, making it a dependable choice for industries that demand exacting tolerances.

Enhanced User Control and Safety

With hand-operated, mechanical controls and a magnetic chuck, the RI-4 offers safe, user-friendly operation without the need for complex CNC systems. The built-in coolant and lubrication systems contribute to consistent tool performance and extended machine lifespan.

FAQs of SASS Italy RI-4 Internal Grinder Machine:

Q: How is lubrication managed on the SASS Italy RI-4 Internal Grinder Machine?

A: The RI-4 features a centralized manual lubrication system, ensuring all essential components receive adequate lubrication during operation, which extends machine life and maintains smooth performance.Q: What types of materials can be processed with the RI-4 Internal Grinder?

A: This grinder is suitable for internal grinding operations on materials like cast iron and steel components, making it versatile for a range of workshop and manufacturing applications.Q: When should I use the integral coolant system?

A: The integral coolant system should be used throughout grinding operations to control heat, prevent workpiece warping, and prolong the durability of both the machine and grinding wheel.Q: Where is the RI-4 Internal Grinder most effectively utilized?

A: This machine excels in environments such as manufacturing workshops, repair shops, and component production lines where high-accuracy internal grinding is essential.Q: What is the process for setting up a workpiece on the RI-4?

A: To set up, position the workpiece on the 100 mm magnetic chuck, adjust the table travel (up to 120 mm), and manually control both the table and spindle to achieve precise alignment before grinding.Q: How does the RI-4 benefit manual operation over CNC alternatives?

A: The manual operation allows for straightforward setup, user-driven adjustments, and intuitive use, making it highly suitable for custom, small-batch, or varied grinding tasks.Q: What are the key advantages of using the RI-4 Internal Grinder for my workshop?

A: Key benefits include high grinding accuracy, robust cast iron construction, easy maintenance, integral coolant and lubrication systems, and a compact footprint designed for efficient space utilization.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Internal Grinding Machine Category

Voumard Switzerland Type 5A Internal Grinding Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 2.2 kW to 3 kW

Type : Other, Voumard Type 5A

Material : Other, Cast iron, steel, precision components

Product Type : Internal Grinding Machine

Nolaf France Internal Grinder with Face Grinding Attachment

Price 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 2.2 kW

Type : Other, Bench Type / Floor Mounted

Material : Other, Heavy Duty Cast Iron Bed

Product Type : Internal Grinder with Face Grinding Attachment

Schaudt Long Table Internal Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 7.5 kW

Type : Other, Long Table Internal Grinder

Material : Other, Cast iron, precision ground

Product Type : Internal Grinder

WMW SI 400 x 500 Heavy Duty Internal Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 9 kW

Type : Other, Heavy Duty Industrial

Material : Other, Cast Iron / Graded Steel

Product Type : Internal Grinder

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry