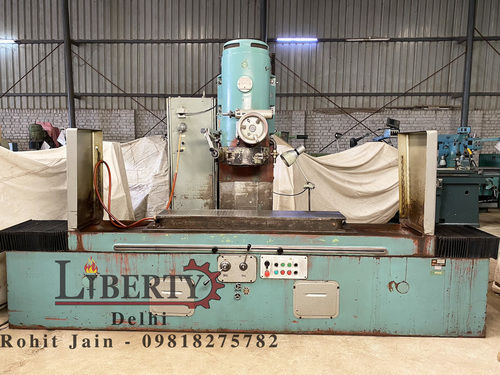

Taiwan 355 mm x 710 mm Surface Grinding Machine

Price 15000 INR/ Piece

Taiwan 355 mm x 710 mm Surface Grinding Machine Specification

- Model

- Taiwan 355 x 710

- Rotation

- Clockwise

- Product Type

- Surface Grinding Machine

- General Use

- Precision surface grinding of metals and other materials

- Material

- Cast Iron, Steel

- Type

- Manual Surface Grinder

- Capacity

- Heavy Duty

- Weight (kg)

- Approx. 2200 kg

- Computerized

- No

- Automatic

- No

- CNC Or Not

- Not CNC

- Control System

- Manual

- Table Size

- 355 mm x 710 mm

- Table Slide Way

- Double V

- Magnetic Chuck Size

- 355 mm x 710 mm

- Grinding Wheel Size

- 355 mm x 38 mm x 127 mm

- Grinding Wheel Speed

- 1450 RPM

- Grinding Length

- 710 mm

- Floor Space

- 2200 mm x 1700 mm

- Fuel Tank Capacity

- 90 liters

- WorkingSpeed

- Constant

- Spindle Speed

- 1450 RPM

- Power

- 5 HP (approx. 3.7 kW)

- Voltage

- 415 V, 3 Phase

- Dimension (L*W*H)

- 2200 mm x 1700 mm x 1700 mm

- Feature

- High Precision, Durable Construction

- Color

- Standard Industrial Grey

Taiwan 355 mm x 710 mm Surface Grinding Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About Taiwan 355 mm x 710 mm Surface Grinding Machine

Make - Ta-Fu-Yuan (Taiwan)

Model - MPS-350

Magnet Size - 355 mm x 710 mm

Cross Travel of Table - 400 mm

Longitudinal Travel of Table - 750 mm

Max. Distance b/w Wheel Center & Magnet Top - 450 mm

Grinding Wheel Size - Diameter 305 mm x 50 mm Width

- With Automatic Depth Adjustment "Auto-Cut".

- Motorised Rapid Travel in Vertical & in Cross Travel.

- Equipped with a 2-Axis DRO.

- With Coolant Tank & Pump, Spare Wheel & Flange, Wheel Dresser etc.

- Machine is in excellent working condition.

Video Link-

Precision Surface Grinding

Achieve meticulous accuracy on metal parts with the Taiwan 355 x 710 Surface Grinding Machine. With a precision of 0.005 mm and an electromagnetic chuck, your workpieces remain stable during operation, resulting in a flawless finish. This model is ideal for toolrooms, die & mold workshops, and general manufacturing environments that demand superior surface quality and consistency.

Heavy-Duty Performance

Engineered with a powerful 3.7 kW spindle motor and hydraulic table feed, this surface grinder is built for durability and continuous use in demanding settings. Its solid cast iron and steel construction minimizes vibration, ensuring both operator safety and part accuracy. The machine also offers a centralized lubrication system and integrated coolant for efficient cooling and prolonging tool life.

FAQs of Taiwan 355 mm x 710 mm Surface Grinding Machine:

Q: How does the Taiwan 355 x 710 Surface Grinding Machine achieve high precision?

A: This machine is constructed with a double V table slide way and utilizes an electromagnetic chuck to secure workpieces. Its advanced features, including centralized lubrication and a precise spindle motor, enable repeatable surface accuracies down to 0.005 mm.Q: What types of materials can this surface grinder process effectively?

A: The surface grinder is designed to handle metals such as cast iron and steel, making it suitable for toolrooms, metal parts finishing, and die & mold workshops. It is capable of grinding various other materials requiring precise surface finishes as well.Q: When should I use the automatic cross feed versus manual vertical feed?

A: Automatic or electric cross feed is ideal for consistent, large-scale grinding operations, ensuring uniform surface movement across the workpiece. The manual vertical feed provides control for precision adjustments, optimal for tasks requiring specific depth or finishing touches.Q: Where is the Taiwan 355 x 710 Surface Grinding Machine commonly installed?

A: This model is typically found in toolrooms, die and mold workshops, and manufacturing plants that require heavy-duty precision surface grinding on metal parts. Its floor space requirement is approximately 2200 mm x 1700 mm.Q: What is the process for maintaining the centralized lubrication and coolant systems?

A: Regularly check oil levels and refill lubricants as needed to ensure all moving parts are properly maintained. The coolant system should be inspected, cleaned, and replenished to avoid overheating and ensure smooth grinding operations.Q: How does using a hydraulic table feed benefit production?

A: Hydraulic table feed allows for smooth, variable-speed table movement, reducing operator fatigue, improving surface uniformity, and enabling efficient heavy-duty grinding operations over long periods.Q: What are the main benefits of choosing this manual surface grinder over CNC models?

A: Manual control provides greater hands-on flexibility and is well-suited to custom, low-volume tasks, maintenance, or specialized jobs. With its high durability, precision, and ease of operation, this machine offers an excellent cost-to-benefit ratio for workshops focusing on skilled manual grinding tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Surface Grinder Category

MAS BPV 300 x 1500 Vertical Surface Grinder

Price 33000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Automatic : No

Color : Other, Standard Grey

CNC Or Not : Other, Not CNC (Conventional)

Magerle Surface Grinding Machine

Price 5000 USD ($)

Minimum Order Quantity : 1 Piece

Computerized : No

Automatic : No

Color : Other, White & Blue

CNC Or Not : Other, Not CNC

Alpa RT 800 Surface Grinding Machine

Price 6000 INR

Minimum Order Quantity : 1 Piece

Computerized : No

Automatic : No

Color : Other, Standard Grey/Blue

CNC Or Not : Other, No

Delta LC-400 Vertical Rotary Surface Grinder Machine

Price 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : Yes

Automatic : Yes

Color : White

CNC Or Not : CNC

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry