TOS 2000 mm Cylindrical Grinder

TOS 2000 mm Cylindrical Grinder Specification

- Product Type

- Cylindrical Grinder

- General Use

- Heavy Duty Precision Grinding

- Material

- Cast Iron Body

- Type

- Universal Cylindrical Grinding Machine

- Capacity

- 2000 mm

- Weight (kg)

- Approx. 6300 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- Control System

- Manual/Hand Operated

- Drive Type

- Mechanical Belt Driven

- Grinding Diameter

- 320 mm

- Grinding Length

- 2000 mm

- Spindle Speed

- Up to 1200 rpm

- Grinding Wheel Size

- 500 mm x 80 mm x 203.2 mm

- Voltage

- 415 V, 3 Phase, 50 Hz

- Dimension (L*W*H)

- 4800 mm x 2000 mm x 1700 mm

- Feature

- Good Quality

- Color

- Green/Grey

- Chuck Size

- Optional as per job size

- Workhead Centre Taper

- MT-5

- Maximum Job Weight Between Centers

- 700 kg

- Surface Finish Achievable

- Up to 0.5 Ra

- Tailstock Centre

- MT-5

- Cross Feed Travel

- 250 mm

- Maximum Swing Over Bed

- 390 mm

- Table Longitudinal Travel

- 2200 mm

- Coolant System

- Provided

- Lubrication System

- Centralized

About TOS 2000 mm Cylindrical Grinder

Make - TOS-Hostivar (Czech Republic)

Model - B40U/2000

Center Height - 205 mm

Max. Diameter of Job - 400 mm

Length of Job - 2000 mm

Grinding Wheel Size - 500 mm Diameter x 100 mm Width

Work-Head Speed - 15 rpm to 375 rpm

With Internal Grinding Attachment.

Automatic Depth Adjustment "Auto-Cut".

Complete with 3 x 2-point steadies.

With Wheel Dresser, Angular Wheel Dresser & Internal Grinding Wheel Dresser.

With Wheel Balancing arrangement, coupling, chuck, all covers etc.

- Complete with coolant tank and pump.

- Machine is in excellent working condition.

Video Link - https://youtu.be/ij9D9zAUrG8

Precision Heavy-Duty Grinding

Designed for demanding industrial environments, the TOS 2000 mm Cylindrical Grinder offers a large grinding capacity and advanced features for high precision. The machines mechanical belt-driven system ensures stable operation, while MT-5 workhead and tailstock centers support versatility across a broad range of job sizes and materials.

Efficient Operation and Maintenance

Equipped with a centralized lubrication system and a high-performance coolant system, the grinder facilitates smooth functioning and minimal maintenance effort. The semi-automatic, manual control interface allows skilled operators to fine-tune processes for maximum accuracy and reliability during grinding operations.

Versatility for Multiple Applications

Suitable for exporters, importers, manufacturers, and suppliers, this cylindrical grinding machine can handle long workpieces up to 2000 mm. Its adaptable chuck size and robust design make it ideal for producing precision components across various industrial sectors, offering consistent quality and repeatability.

FAQs of TOS 2000 mm Cylindrical Grinder:

Q: How does the TOS 2000 mm Cylindrical Grinder ensure high precision in heavy-duty jobs?

A: The grinder incorporates a solid cast iron body, MT-5 workhead and tailstock centers, and offers a maximum swing over bed of 390 mm. Its mechanical belt-driven system and semi-automatic controls allow operators to maintain precise grinding with an achievable surface finish of up to 0.5 Ra.Q: What is the process for setting up different sized jobs on the machine?

A: The machine features optional chuck sizes and accommodates workpieces up to 2000 mm in length and 700 kg in weight. Operators can adjust fixtures and select appropriate chucks according to job size requirements for optimal positioning between centers and secure mounting.Q: When should the centralized lubrication and coolant systems be checked?

A: Routine checks and maintenance of both the centralized lubrication and coolant systems are recommended before each grinding session. Regular monitoring ensures smooth operation, reduces wear, and prolongs machine life in intensive production settings.Q: Where is the TOS 2000 mm Cylindrical Grinder commonly used?

A: This grinder is widely utilized in industrial manufacturing environments by exporters, importers, manufacturers, and suppliers. It excels in heavy-duty precision work, making it suitable for workshops and factories needing reliable cylindrical grinding solutions.Q: What materials can this cylindrical grinder process efficiently?

A: With its heavy cast iron construction and robust spindle, the machine is designed to efficiently grind steel, cast iron, and similar materials requiring high-accuracy surface finishing in large-scale operations.Q: How does the manual control system benefit users?

A: The manual control system allows operators to have direct, hands-on control over grinding operations. This flexibility helps skilled personnel adjust settings quickly, ensuring optimal surface quality and safety during both setup and production.Q: What are the main advantages of choosing the TOS 2000 mm Cylindrical Grinder for your facility?

A: Key benefits include high precision, large work capacity, efficient lubrication and coolant systems, versatile setup for various job sizes, and rugged heavy-duty construction. These features contribute to long-term reliability and consistent quality, making it a preferred choice for heavy manufacturing applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cylindrical Grinder Category

TOS 2UD 1000 mm Universal Cylindrical Grinder Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Universal Cylindrical Grinder Machine

General Use : Precision external and internal grinding of cylindrical and conical surfaces

Voltage : 415 V, 3 Phase, 50 Hz

Weight (kg) : Approx. 3100 kg

Tacota Italy 2700 mm Length Cylindrical Grinder Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Cylindrical Grinder Machine

General Use : Precision grinding of cylindrical components

Voltage : 415 V, 3 Phase, 50 Hz

Weight (kg) : Approx. 6500 kg

Jones Shipman England Precision Universal Cylindrical Grinder Machine

Price 100000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Precision Universal Cylindrical Grinder Machine

General Use : Grinding external and internal cylindrical surfaces

Voltage : 415 V, 3 Phase, 50 Hz

Weight (kg) : Approximately 1800 kg 2500 kg (depending on model)

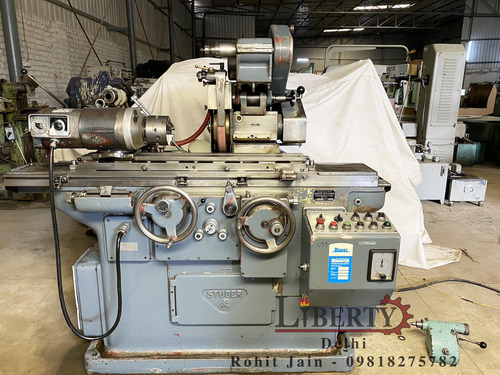

Studer Universal Cylindrical Grinder

Price 13500 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Universal Cylindrical Grinder

General Use : Precision External and Internal Grinding

Voltage : 400 V, 50 Hz

Weight (kg) : 2800 kg (Approx.)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry