TOS BHU 50A / 2000 Universal Cylindrical Grinder

Price 7000 INR/ Piece

TOS BHU 50A / 2000 Universal Cylindrical Grinder Specification

- Product Type

- Universal Cylindrical Grinder

- General Use

- Precision External and Internal Grinding of Cylindrical Parts

- Material

- Cast Iron Body, High-Grade Steel Components

- Type

- Heavy Duty - Hydraulic

- Capacity

- 500 mm x 2000 mm

- Weight (kg)

- Approx. 7000 kg

- Computerized

- No

- Automatic

- Yes

- Control System

- Conventional

- Drive Type

- Electric Motor

- Grinding Diameter

- Max 500 mm

- Grinding Length

- Max 2000 mm

- Spindle Speed

- 25315 rpm, Stepless

- Grinding Wheel Size

- 500 x 80 x 203 mm

- Voltage

- 415 V, 50 Hz, 3 Phase

- Dimension (L*W*H)

- 4840 x 1950 x 1750 mm

- Feature

- Hydraulic Table Movement, Adjustable Tailstock, Sturdy Construction

- Color

- Standard Industrial Grey-Green

- Chuck Type

- Three-Jaw and Four-Jaw (optional)

- Accuracy

- IT6 or better

- Wheel Peripheral Speed

- 33 m/s

- Workhead Spindle Taper

- MT5

- Wheelhead Power

- 4.0 kW

- Maximum Table Traverse

- 2300 mm

- Internal Grinding Attachment

- Optional

- Center Height

- 270 mm

- Maximum Workpiece Weight Between Centers

- 500 kg

- Table Feed Rate

- 0.05 6 m/min (hydraulic stepless)

- Coolant System

- Integrated

- Workhead Spindle Speed

- 25 315 rpm

About TOS BHU 50A / 2000 Universal Cylindrical Grinder

Make - TOS-Hostivar (Czech Republic)

Model - BHU 50 A / 2000

Center Height - 255 mm

Max. Diameter of Job - 500 mm

Grinding Length of Job - 2000 mm

Grinding Wheel Size - Diameter 500 mm x 100 mm Width

Work-Head Speeds - 18 rpm to 560 rpm

Least Count - 1 Micron

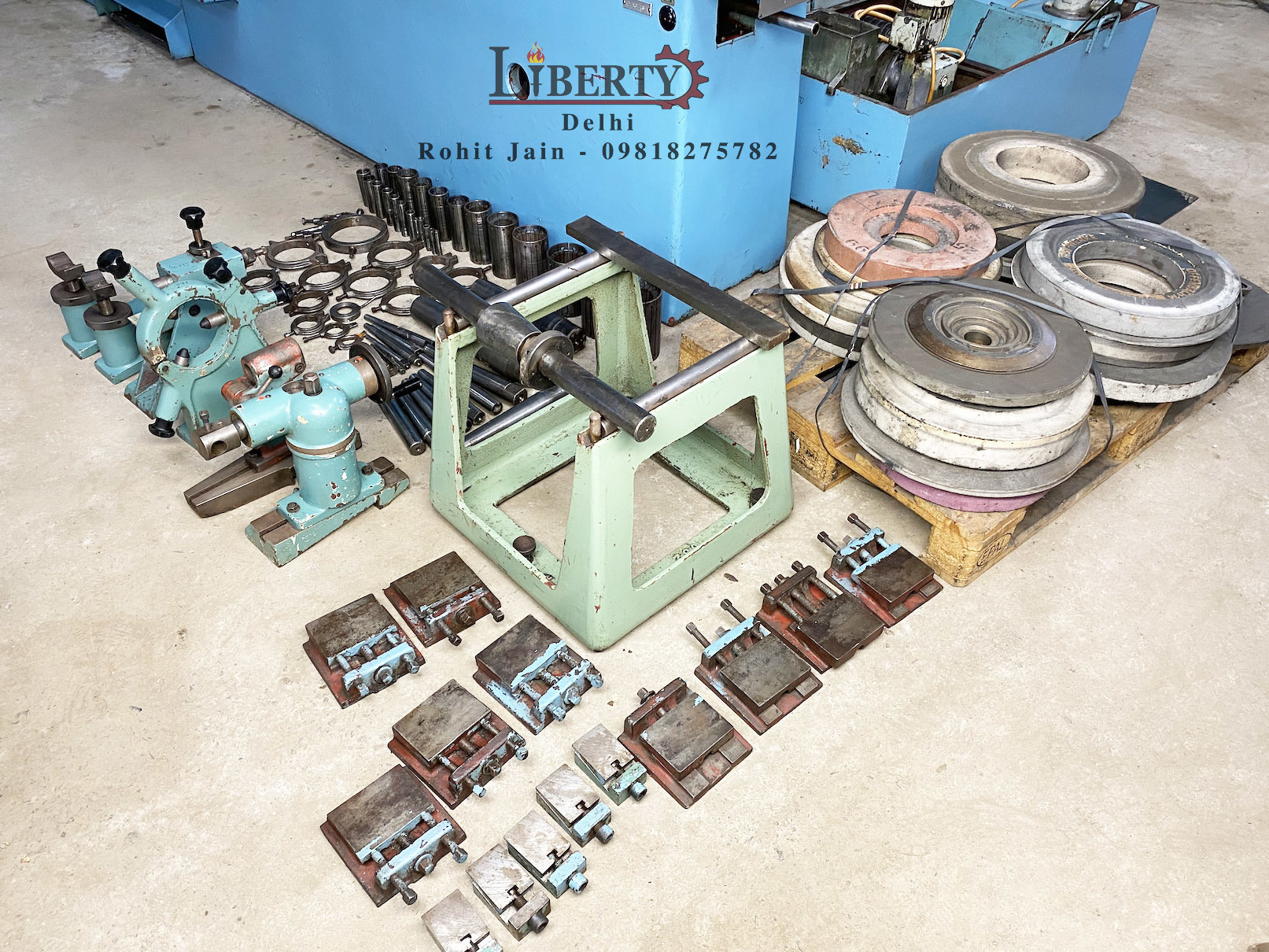

- Equipped with Internal Grinding Attachment.

- Complete with 2-point steady, 3-point steady and 2 x job supports.

- Complete with 2 x Wheel Dresser, Side Wheel Dresser, Wheel Balancing Stand.

- Lots of Accessories like Collets, Mandrels, Job Carriers etc.

- Features like Delay, Auto-Slow, Rapid Travel of the Table etc.

- Features like Automatic Depth Adjustment, Plunge Grinding, Auto Compensate etc.

- With Magnetic Coolant Filtration Unit, coolant pump and tank, splash guards etc.

- One of the latest series of conventional machines made by TOS (Joy-stick model).

- Operating manual & electrical circuit drawings available.

- Machine is in excellent working condition.

Video link - https://youtu.be/CvXpUMeCGJk

Precision Grinding Performance

Engineered for accuracy to IT6 or better, the TOS BHU 50A / 2000 ensures consistent results in both external and optional internal grinding processes. Its robust construction and advanced feed mechanisms enable high-quality finishes on a variety of materials, making it ideal for demanding industrial applications.

Versatile Workpiece Handling

With a maximum workpiece weight of 500 kg and a grinding length up to 2000 mm, this universal grinder accommodates a wide range of cylindrical components. The adjustable tailstock and multiple chuck options enable flexible setup, while the hydraulic table movement streamlines operation and enhances productivity.

Efficient and Reliable Operation

A powerful 4.0 kW wheelhead and integrated coolant system keep grinding conditions optimal, prolonging tool life and safeguarding component quality. Easy-to-use conventional controls and automatic functions allow operators to focus on precision while the machine manages consistency and repeatability.

FAQs of TOS BHU 50A / 2000 Universal Cylindrical Grinder:

Q: How is the TOS BHU 50A / 2000 Universal Cylindrical Grinder operated?

A: The grinder operates automatically with a conventional control system. Its hydraulic table movement and electric motor drive facilitate efficient, precise grinding, while the user can easily adjust parameters such as spindle speed and feed rate for specific requirements.Q: What types of workpieces can the TOS BHU 50A / 2000 accommodate?

A: It can handle cylindrical workpieces with a maximum diameter of 500 mm, length up to 2000 mm, and weight between centers up to 500 kg. The grinder is suitable for external and, optionally, internal grinding of heavy-duty components, including high-grade steel and cast iron parts.Q: When is the internal grinding attachment required with this machine?

A: The internal grinding attachment is optional and should be used when operations require machining internal surfaces of cylindrical components. This is distinct from standard external grinding, which the machine supports by default.Q: Where is this universal cylindrical grinder manufactured and supplied?

A: TOS BHU 50A / 2000 grinders are manufactured in the Czech Republic and are available globally through exporters, importers, manufacturers, suppliers, and traders specializing in industrial grinding machines.Q: What is the process for adjusting the grinding operation parameters?

A: Operators can set table feed rates steplessly from 0.05 to 6 m/min using the hydraulic system and adjust spindle speeds between 25 and 315 rpm. Tailstock and chuck types can be changed as needed, and coolant flow is managed by the integrated system, enabling precise control over grinding conditions.Q: How does the integrated coolant system benefit grinding operations?

A: The built-in coolant system maintains optimal grinding temperatures, prevents workpiece distortion, and extends grinding wheel life. This results in higher accuracy and longer intervals between maintenance, enhancing overall productivity.Q: What are the main usage advantages of this universal grinder?

A: Key advantages include high accuracy, heavy-duty construction, versatility for both external and internal grinding, customizable setup via chucks and attachments, and efficient hydraulic table movement. These ensure top performance in precision manufacturing environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cylindrical Grinder Category

Ribon RUR-1000 Universal Cylindrical Grinding Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Heavyduty Cast Iron and Steel

General Use : Precision external and internal grinding of cylindrical components

Drive Type : Other, Belt Driven

Control System : Other, Manual control handwheels

TOS BHU40A 1500 mm Length Universal Cylindrical Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Cast Iron Body and Hardened Steel Components

General Use : Precision external and internal grinding of cylindrical parts

Drive Type : Electric

Control System : Other, Conventional

Kellenberger 1000U High Precision Cylindrical Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Cast iron base, steel components

General Use : Industrial use for precision grinding of cylindrical components

Drive Type : Electric

Control System : Other, CNC

Nolaf France Universal Cylindrical Grinder Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Cast Iron, Steel

General Use : Industrial Grinding Applications

Drive Type : Other, Electric Motor Driven

Control System : Other, Handoperated/PLC (optional)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry