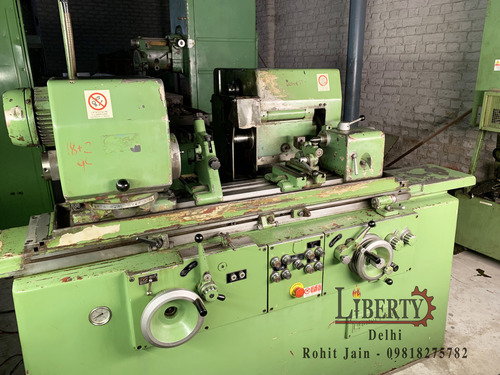

TOS BUA 31 x 1000 mm Universal Cylindrical Grinder

Price 100000 INR/ Piece

TOS BUA 31 x 1000 mm Universal Cylindrical Grinder Specification

- Product Type

- Universal Cylindrical Grinder

- General Use

- Precision external and internal grinding of cylindrical and conical surfaces

- Material

- Cast Iron / Steel

- Type

- Heavy Duty

- Capacity

- 1000 mm (Length between centers)

- Weight (kg)

- Approx. 3700 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- Control System

- Manual

- Drive Type

- Electric

- Grinding Diameter

- 320 mm (Max)

- Grinding Length

- 1000 mm

- Spindle Speed

- 35500 RPM (workpiece spindle variable)

- Grinding Wheel Size

- 400 x 50 x 203 mm

- Voltage

- 380/415 V, 3 Phase, 50 Hz

- Dimension (L*W*H)

- 3100 x 1800 x 1400 mm (Approx.)

- Feature

- Universal, Suitable for high precision, Optional internal grinding attachment

- Color

- Light Blue/Grey (Standard Factory Color)

- Frequency

- 50 Hz

- Tailstock Quill Travel

- 50 mm

- Max. Workpiece Weight

- 150 kg (between centers)

- Lubrication System

- Centralized automatic lubrication

- Main Motor Power

- 4.0 kW

- Coolant System

- Yes (standard with machine)

- Max. Swing Over Bed

- 320 mm

- Wheel Peripheral Speed

- 30 m/s

- Internal Grinding Spindle Speed

- 12000 RPM

- Rapid Traverse Speed

- 2.5 m/min

- Centre Height

- 180 mm

- Longitudinal Table Traverse

- 1100 mm

- Minimum Workpiece Diameter

- 8 mm

- Workhead Taper

- MT4

- Wheelhead Motor Power

- 3.5 kW

TOS BUA 31 x 1000 mm Universal Cylindrical Grinder Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About TOS BUA 31 x 1000 mm Universal Cylindrical Grinder

Make - TOS-Hostivar (Czech Republic)

Model - BUA 31/1000

Center Height - 160 mm

Max. Length of Job - 1000 mm

Max. Diameter of Job - 320 mm

Grinding Wheel Size - Diameter 500 mm x 90 mm Width

Work-Head Speeds - 15 rpm to 375 rpm

Least Count - 1 Micron (0.001 mm)

- Equipped with Internal Grinding Attachment.

- Features like Auto-Cut, Auto-Compensation, Plunge Grinding etc.

- Features like Delay, Auto-Slow, Auto Wheel Retraction etc.

- Equipped with a Hydraulic Tail-Stock.

- Complete with Magnetic Coolant Filtration Unit, Coolant Tank & Pump.

- Machine is in excellent working condition.

Video of The Machine -

Engineered for Precision and Flexibility

The TOS BUA 31 x 1000 mm Universal Cylindrical Grinder is designed for both external and internal grinding of heavy-duty components, offering high accuracy in shaping cylindrical and conical surfaces. Its manual, semi-automatic control and variable spindle speeds allow operators to adapt the grinding process to diverse production requirements.

Robust Construction and Reliable Performance

Constructed from cast iron and steel, this grinder features a center height of 180 mm and supports workpieces up to 150 kg. The 4.0 kW main motor ensures stable operation while the centralized automatic lubrication system increases longevity and reduces maintenance needs. Designed for industrial use, it handles rigorous demands efficiently.

Versatility with Advanced Features

This model provides a maximum grinding length of 1000 mm and a swing over bed of 320 mm, accommodating a wide range of workpiece sizes. The optional internal grinding attachment and high-speed spindle (up to 12,000 RPM) broaden its capabilities. Safety and operation are enhanced with a standard coolant system and ergonomic controls.

FAQs of TOS BUA 31 x 1000 mm Universal Cylindrical Grinder:

Q: How does the TOS BUA 31 x 1000 mm cylindrical grinder ensure precision in grinding operations?

A: The machine is built with a rigid cast iron and steel structure, offering high stability during grinding. Its variable speed control, centralized automatic lubrication, and precision spindle system contribute to consistent and accurate material removal, making it suitable for high-precision requirements.Q: What types of workpieces can be processed with this grinder?

A: This universal cylindrical grinder accommodates workpieces made of cast iron or steel, with diameters ranging from 8 mm up to 320 mm and lengths up to 1000 mm. It is designed for grinding both cylindrical and conical surfaces across various industries.Q: When should the internal grinding attachment be used?

A: The optional internal grinding attachment should be used when internal surfaces require precision finishing, particularly in components with tight tolerance requirements. It is ideal when internal diameters demand high rotational speeds, as the spindle can reach up to 12,000 RPM.Q: Where is the TOS BUA 31 x 1000 mm cylindrical grinder typically utilized?

A: This machine is commonly found in industrial workshops, manufacturing plants, and tool rooms requiring precision grinding for heavy-duty and high-accuracy applications, particularly in export, manufacturing, and supply sectors.Q: What is the process for setting up workpieces between centers?

A: To set up a workpiece, secure it between the headstock and tailstock (with a center height of 180 mm). Adjust the tailstock quill (50 mm travel) for positioning and ensure firm clamping. The machines workhead uses a MT4 taper for stable mounting, supporting workpieces up to 150 kg.Q: How does the coolant system benefit grinding operations?

A: The built-in coolant system efficiently dissipates heat generated during grinding, minimizing thermal expansion and reducing the risk of burns or material damage. This enhances both surface finish quality and machine longevity.Q: What are the advantages of choosing this semi-automatic, manual-control grinder?

A: The TOS BUA 31 x 1000 mm combines flexibility with robust performance. Semi-automatic features streamline repetitive tasks, while manual controls allow operators to adapt to specific workpiece requirements, making the machine suitable for both standard and customized precision grinding jobs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cylindrical Grinder Category

Grisetti Italy 1650 mm Length Universal Cylindrical Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Electric

Grinding Length : 1650 mm

General Use : Industrial Grinding Operations

Color : Other, Industrial Grey

Fortuna Germany Polygon and Cylindrical Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Other, Electric Motor Drive

Grinding Length : 500 mm

General Use : Precision grinding of polygons and cylindrical parts

Color : Other, Green / Standard Fortuna Finish

Universal Cylindrical Grinder

Price 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Other, Belt Drive

Grinding Length : 500 mm

General Use : Precision external and internal grinding of cylindrical surfaces

Color : Other, Light Gray & Blue

Olivetti R5 Cylindrical Grinder

Price 1100 INR

Minimum Order Quantity : 1 Piece

Drive Type : Electric

Grinding Length : Max 1000 mm

General Use : Precision external and internal grinding of cylindrical components

Color : Other, Olive green

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry