TOS OH6 Gear Shaping Machine

Price 100000 INR/ Piece

TOS OH6 Gear Shaping Machine Specification

- Dimension (L*W*H)

- 1700 x 1200 x 2200 mm

- Weight

- Approximately 2200 kg

- Feature

- High Precision, Robust Structure, Smooth Operation

- Capacity

- Maximum Gear Diameter 650 mm

- Output

- High Accuracy Gear Cutting

- Machine Type

- Gear Shaping Machine

- Voltage

- 380V / 415V

- Color

- Green

- Used For

- Internal and External Gear Shaping

- Power

- 7.5 kW

- Condition

- Used

- Number of Strokes per Minute

- 45 - 400

- Table Hole Diameter

- 90 mm

- Maximum Weight of Workpiece

- 350 kg

- Control Type

- Manual

- Maximum Cutting Stroke

- 160 mm

- Feed Adjustment

- Available

- Spindle Speed

- 60 - 400 RPM

- Maximum Module

- 8

- Maximum Workpiece Height

- 160 mm

- Made By

- TOS

- Table Diameter

- 630 mm

TOS OH6 Gear Shaping Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About TOS OH6 Gear Shaping Machine

Make - TOS (Czech Republic)

Model - OH-6

Max. Module Capacity - 6 Modules

Gear Diameter - 500 mm

Max. Stroke Length - 105 mm

Stroke Rate - 50 strokes/min to 315 strokes/min

- Complete with lots of Cutters & Change Gears.

- With lots of Mandrels, Fixtures and a lot of other accessories.

- Operating Manual and Electrical Drawings are available.

- Machine is in excellent working condition.

Video of the Machine -

https://youtube.com/watch?v=

Engineered for High Precision and Robustness

TOS OH6 stands out for its high precision and durable construction, making it suitable for detailed gear shaping. The machine is tailored for both internal and external gear profiles, ensuring versatility in operation while maintaining structural integrity during heavy-duty tasks.

Versatile Shaping Capabilities

With a maximum gear diameter of 650 mm and adjustable feed, the OH6 can process various gear types efficiently. The manual controls offer flexibility to operators, while the broad range of strokes per minute and spindle speeds accommodate different cutting and finishing needs.

Reliable Performance for Industrial Needs

Weighing approximately 2200 kg and powered by a 7.5 kW motor, the TOS OH6 Gear Shaping Machine is built for continuous, stable operation. Its smooth mechanism supports high accuracy gear cutting, which is essential for industries requiring dependable and consistent output.

FAQs of TOS OH6 Gear Shaping Machine:

Q: How does the TOS OH6 Gear Shaping Machine ensure high accuracy in gear cutting?

A: The machine combines robust construction with advanced feed adjustment and manual control, allowing precise gear shaping. Its smooth operation and stable structure minimize vibration, contributing to high-accuracy results even during extended use.Q: What types of gears can be shaped with the TOS OH6 machine?

A: The TOS OH6 is designed for both internal and external gear shaping. It can handle gear modules up to 8 and workpieces with a maximum diameter of 650 mm, making it versatile for various gear sizes and types.Q: When is manual control beneficial during the gear shaping process?

A: Manual control is advantageous when fine-tuning adjustments are required or when dealing with specialized or non-standard gear profiles. It provides operators with direct oversight, ensuring optimal performance and precision for unique shaping tasks.Q: Where is the TOS OH6 Gear Shaping Machine manufactured and what is its power requirement?

A: This machine is made in the Czech Republic and requires a power input of 7.5 kW, operating on either 380V or 415V, which meets the standards of most industrial settings.Q: What is the process for using the TOS OH6 for internal and external gear shaping?

A: Set up the workpiece on the 630 mm diameter table and select the desired spindle speed and stroke range based on your gear specifications. Adjust the feed as needed, use manual controls for precision, and start the shaping process. The machines mechanism ensures consistent and accurate cuts on both internal and external surfaces.Q: What are the main benefits of using this gear shaping machine in a manufacturing setup?

A: Key benefits include its high precision, robust and long-lasting structure, smooth operation, and the capacity to handle large and heavy workpieces. It is ideal for manufacturers seeking quality, efficiency, and reliability in their gear production operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Shapers Category

TOS OH-6 Gear Shaper Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : Used

Used For : Internal and External Gear Cutting

Color : Green

Machine Type : Gear Shaper Machine

Sykes V10B Rack Cutting Gear Shaper

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : Used

Used For : Precision rack gear shaping

Color : Machine Grey

Machine Type : Rack Cutting Gear Shaper

Maag SH-75 Gear Shaping Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : Used

Used For : Industrial Gear Cutting and Shaping

Color : Industrial Blue

Machine Type : Gear Shaping Machine

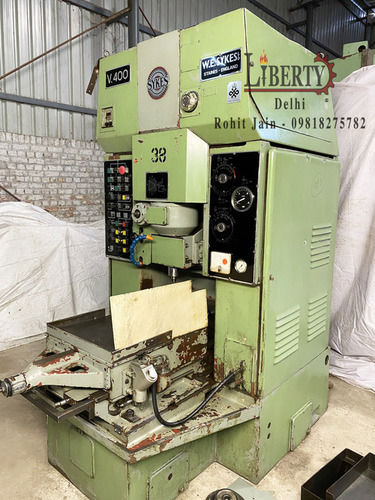

Sykes V400 High Speed Gear Shaper

Price 7300 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : Used

Used For : Gear manufacturing and shaping

Color : Green

Machine Type : Gear Shaper

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry