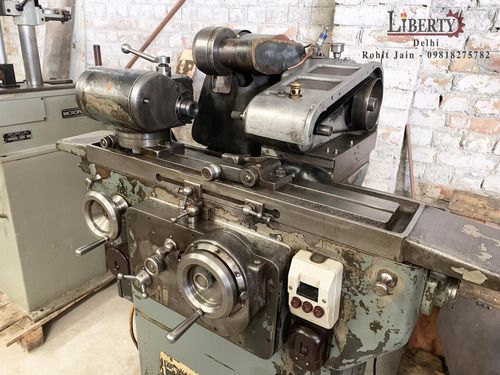

Tripet MAR 200 Precision Internal Grinder

Price 45000 INR/ Piece

Tripet MAR 200 Precision Internal Grinder Specification

- Rotation

- Left & Right Spindle Rotation (Manual Selection)

- Model

- MAR 200

- Product Type

- Precision Internal Grinder

- General Use

- Internal Grinding for High-Precision Components

- Material

- Cast Iron Body

- Type

- Vertical/Horizontal Internal Grinding

- Capacity

- 200 mm grinding length

- Weight (kg)

- Approx. 950 kg

- Computerized

- No

- Automatic

- No

- CNC Or Not

- Not CNC (Conventional)

- Control System

- Manual

- Table Size

- Approx. 600 mm x 200 mm

- Table Slide Way

- Precision V-Flat Hand Scraped

- Magnetic Chuck Size

- 120 mm

- Grinding Wheel Size

- 250 mm x 25 mm

- Grinding Wheel Speed

- Up to 27,000 rpm

- Grinding Length

- 200 mm

- Floor Space

- Approx. 1,200 mm x 900 mm

- Fuel Tank Capacity

- 25 Litres (Coolant)

- WorkingSpeed

- Manual Feed, Variable Speed

- Spindle Speed

- Variable, up to 60,000 rpm

- Power

- 2.2 kW

- Voltage

- 380V / 3 Phase / 50Hz

- Dimension (L*W*H)

- 1,200 x 900 x 1,600 mm

- Feature

- High Accuracy, Durable Construction, Smooth Operation

- Color

- Light Green

- Precision

- 0.001 mm (micron accuracy)

- Quill Bore Capacity

- 3 mm to 120 mm

- Workhead Speed

- Variable, up to 200 rpm

- Max Workpiece Weight

- 40 kg

- Headstock Spindle Taper

- ISO 30

- Coolant System

- Integrated

- Lubrication System

- Centralized, automatic

- Workhead Motor

- 0.25 kW

- Max Workpiece Length

- 200 mm

- Spindle Motor Type

- High-frequency motor

- Swing Over Table

- 200 mm

Tripet MAR 200 Precision Internal Grinder Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About Tripet MAR 200 Precision Internal Grinder

Make - Albert Tripet (Switzerland)

Model - MAR 200

Internal Grinding Diameter - 1 mm to 60 mm

Max. Outside Job Diameter - 220 mm

Grinding Length - 3 mm to 200 mm

Max. Table Travel - 420 mm

Work-Head Swivel Angle - 0 degree to 90 degree

Work-Head Speeds - 150 rpm to 1500 rpm

Max. Spindle Speeds - 33,000 rpm

Auto-Feed Travels - 0.001 mm to 0.01 mm

Max. Distance between Chuck Face & Spindle Body - 480 mm

Chuck Diameter - 125 mm

Spindle Diameter - 50 mm

- Features like Auto-Cut and Delay etc.

- Equipped Automatic Grinding Wheel Dresser.

- Complete with Coolant Filtration Unit, Tank and Pump.

- Machine is in excellent working condition.

Video of the Machine -

Exceptional Micron-Level Precision

The Tripet MAR 200 delivers precision internal grinding with an accuracy of 0.001 mm, enabling manufacturers to achieve stringent tolerances for high-value components. The machines stable cast iron construction and precision V-flat hand-scraped slideways further enhance repeatability and smooth operation, making it ideal for applications demanding reliable and consistent output.

Adaptable for Varied Grinding Needs

Capable of handling workpieces up to 200 mm in length and a quill bore capacity ranging from 3 mm to 120 mm, the MAR 200 can accommodate diverse part sizes and production requirements. Its manually operated variable speed controls allow for left and right spindle rotation, providing users with flexibility in grinding both vertical and horizontal orientations.

Operator-Friendly & Durable Design

Featuring a manual, non-CNC control system, the Tripet MAR 200 is designed for skilled operators who require hands-on control. The centralized automatic lubrication system reduces maintenance, while an integrated coolant system increases tool longevity. This durable grinder is constructed for continuous industrial use and is built to last.

FAQs of Tripet MAR 200 Precision Internal Grinder:

Q: How does the Tripet MAR 200 ensure high-precision grinding results?

A: The MAR 200 achieves exceptional precision with its micron-level accuracy (0.001 mm), rigid cast iron construction, and precision-engineered V-flat hand-scraped slideways. These features collectively minimize vibration and enable consistent, ultra-fine internal grinding.Q: What types of components can be processed on this internal grinder?

A: This grinder is suited for a range of high-precision components up to 200 mm in length, including bushings, sleeves, and bearing housings requiring tight tolerances for industries such as aerospace, automotive, and mechanical engineering.Q: When should I consider using a non-CNC internal grinder like the MAR 200?

A: The MAR 200 is ideal when precise manual control is needed, particularly for prototype work, small batch production, or operations requiring the skills of a trained machinist for nuanced adjustments rather than automated CNC sequences.Q: Where is the Tripet MAR 200 typically installed and used?

A: Thanks to its moderate footprint (1,200 x 900 mm) and robust construction, the MAR 200 is well-suited for installation in precision engineering workshops, tool rooms, and manufacturing plants engaged in high-accuracy internal grinding tasks.Q: What is the process for adjusting the workhead and spindle speeds?

A: Both the workhead and spindle speeds are variable and can be manually adjusted by the operator, allowing optimization for different materials and grinding requirements. The spindle can reach up to 60,000 rpm, and the workhead up to 200 rpm.Q: How does the integrated coolant and lubrication system benefit operation?

A: The integrated coolant system, with a 25-litre tank, helps control grinding temperatures, extending the life of the grinding wheel and enhancing finish quality. The centralized automatic lubrication system ensures smooth movement and reduces maintenance.Q: What are the primary benefits of using the Tripet MAR 200 for internal grinding applications?

A: Key benefits include outstanding accuracy, durable construction for long equipment life, operator flexibility due to manual controls, and a comprehensive system setup (coolant, lubrication) that supports efficient, reliable, and high-quality grinding results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Internal Grinding Machine Category

Voumard Switzerland Type 5A Internal Grinding Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : Other, No, manual operation

Control System : Other, Electrical panel with selector switches

CNC Or Not : Other, Not CNC (Conventional) manual machine

Voltage : 380 / 415 V AC, 3 phase

Voumard 650 mm Diameter Internal Grinder Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : Other, No, manual operation

Control System : Other, Manual with dial gauges

CNC Or Not : Other, Not CNC (Conventional)

Voltage : 415 V, 3 Phase, 50 Hz

Voumard Type 5 Internal Grinding Machine

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : No

Control System : Manual

CNC Or Not : Other, No

Voltage : 380 V / 50 Hz

Morara Bore Grinding Machine

Price 2000 EUR ()

Minimum Order Quantity : 1 Piece

Automatic : Other, No (Manual)

Control System : Manual

CNC Or Not : Other, Conventional

Voltage : 415 V

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry