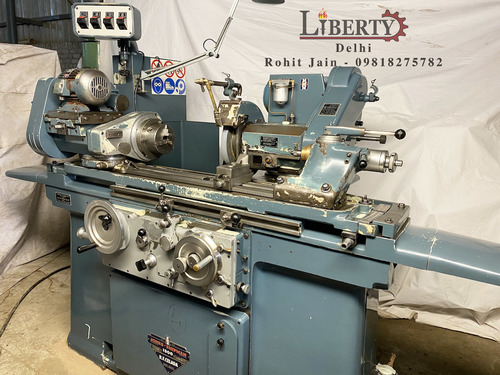

Tschudin HTG 410 High Precision Cylindrical Grinder

Price 100000 INR/ Piece

Tschudin HTG 410 High Precision Cylindrical Grinder Specification

- Product Type

- High Precision Cylindrical Grinder

- General Use

- Precision external and internal cylindrical grinding

- Material

- Cast iron body, hardened steel components

- Capacity

- Between centers: 400 mm

- Weight (kg)

- Approx. 1350 kg

- Computerized

- No

- Automatic

- Semi-automatic

- Control System

- Manual with hydraulic assist

- Drive Type

- Belt-driven

- Grinding Diameter

- 2 160 mm

- Grinding Length

- 400 mm

- Spindle Speed

- Up to 1900 rpm

- Grinding Wheel Size

- 350 mm x 50 mm x 127 mm

- Voltage

- 380V / 3 Phase / 50 Hz

- Dimension (L*W*H)

- 1800 mm x 1350 mm x 1450 mm

- Color

- Industrial Grey & Red

- Internal Grinding Attachment

- Available (optional)

- Coolant System

- Integrated with machine

- Maximum Workpiece Weight

- 70 kg

- Chuck Type

- Standard 3-jaw chuck compatible

- Table Swivel Range

- 7

- Lubrication

- Centralized automatic lubrication system

- Tailstock

- Movable with fine adjustment

- Workhead Swivel Range

- 90

- Wheelhead Motor Power

- 2.2 kW

- Made In

- Switzerland

- Surface Finish Achievable

- Ra 0.2 m

Tschudin HTG 410 High Precision Cylindrical Grinder Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About Tschudin HTG 410 High Precision Cylindrical Grinder

Make - Tschudin (Switzerland)

Model - HTG 410

Center Height - 100 mm

Max. Job Diameter - 200 mm

Max. Grinding Length of Job - 420 mm

Max. Distance between Centers - 500 mm

Grinding Wheel Size - Diameter 350 mm x 50 mm Width

Work-Head Speeds - 65 rpm to 500 rpm

Table Swivel Angle - +9.5 degree to -10 degree

- Equipped with DRO of 1 Micron Resolution.

- Machine can work in complete Auto-Cycle Mode.

- Features like Auto-Cut, Auto-Compensation, Spark-Out, Auto-Wheel Retraction etc.

- Features like Automatic Plunge Grinding, Delay etc.

- High Precision Machine suitable for High Production Auto-Cycle work.

- Machine is in excellent working condition.

Video of The Machine -

Precision and Versatility for Demanding Tasks

The Tschudin HTG 410 is designed for users who demand both accuracy and versatility in cylindrical grinding. Its hydraulic/manual hybrid system, combined with a rigid cast iron structure and hardened steel, makes it suitable for a range of materials and applications. Operators can efficiently grind both internal and external surfaces with options for fine adjustments, making it an ideal solution for tool rooms, manufacturing, and high-accuracy production.

Built for Excellence and Operator Comfort

Crafted in Switzerland, the HTG 410 emphasizes durability, consistent performance, and user-friendly operation. The integrated coolant system and centralized automatic lubrication reduce maintenance downtime, while its ergonomic layout ensures effortless access and adjustment. The universal workhead and precise slide guides simplify setup and changeovers, supporting productivity without compromising quality.

FAQ's of Tschudin HTG 410 High Precision Cylindrical Grinder:

Q: How does the HTG 410 achieve such high surface finish precision?

A: The Tschudin HTG 410 utilizes robust cast iron construction, accurate slide guides, and a stable hydraulic system, supporting vibration-free operation. Combined with an integrated coolant system and centralized automatic lubrication, the machine can reliably achieve surface finishes down to an Ra of 0.2 m.Q: What types of workpieces can be processed on this cylindrical grinder?

A: The HTG 410 is suitable for both external and internal cylindrical grinding on a range of components weighing up to 70 kg, with grinding diameters from 2 to 160 mm and lengths up to 400 mm. Cast iron and hardened steel construction makes it ideal for tool rooms, production lines, and precision component manufacturing.Q: When should I consider adding the optional internal grinding attachment?

A: The internal grinding attachment is beneficial when you need to perform both external and internal grinding tasks on the same machine. It's particularly useful for users requiring versatile part processing without the need to switch machines, increasing efficiency and throughput.Q: Where is the HTG 410 manufactured, and what standards does it adhere to?

A: The Tschudin HTG 410 is manufactured in Switzerland, renowned for engineering excellence. It is built to deliver high levels of dimensional accuracy, reliability, and robustness, consistent with European industrial standards.Q: What is the typical process for setting up a part on the HTG 410?

A: First, secure the workpiece using the compatible 3-jaw chuck or between centers. Adjust the workhead and tailstock as needed for alignment and support. Set the required grinding parameters manually with hydraulic assists. Finally, engage the grinding cycle while monitoring coolant flow and lubrication.Q: How does the centralized automatic lubrication system benefit users?

A: Centralized automatic lubrication ensures consistent distribution of lubricant to key components, reducing wear, minimizing manual maintenance, and prolonging the life of guideways and bearings for continuous precision.Q: What advantages does the semi-automatic control system provide?

A: The manual control with hydraulic assist offers operators precise control over the grinding process, while semi-automatic features increase operational efficiency, reduce fatigue, and maintain consistent part quality during longer production runs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cylindrical Grinder Category

CC France 650 mm Cylindrical Grinder Machine

Price 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Weight (kg) : Approx. 1700 kg

Voltage : 415 V, 50 Hz, 3 Phase

Product Type : Cylindrical Grinder Machine

Control System : Other, Hand Lever/Hydraulic

Jones & Shipman 1300 Universal Cylindrical Grinder

Price 30000 INR / Piece

Minimum Order Quantity : 1 Piece

Weight (kg) : Approx. 2000 kg

Voltage : 415 V, 3 Phase

Product Type : Universal Cylindrical Grinder

Control System : Other, Manual Mechanical

TOS 2000 mm Cylindrical Grinder

Price 17200 INR

Minimum Order Quantity : 1 Piece

Weight (kg) : Approx. 6300 kg

Voltage : 415 V, 3 Phase, 50 Hz

Product Type : Cylindrical Grinder

Control System : Other, Manual/Hand Operated

Jones & Shipman 1076 Cylindrical Grinder

Price 9000 INR / Piece

Minimum Order Quantity : 1 Piece

Weight (kg) : 1200 kg

Voltage : 400V

Product Type : Cylindrical Grinder

Control System : Manual

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry