Voumard Type 5A Internal Grinding Machine

Price 60000 INR/ Piece

Voumard Type 5A Internal Grinding Machine Specification

- Rotation

- Left / Right

- Model

- Voumard 5A

- Product Type

- Internal Grinding Machine

- General Use

- Internal cylindrical grinding of precision components

- Material

- Cast Iron/Steel

- Type

- Voumard Type 5A

- Capacity

- 100 mm - 250 mm dia. workpiece

- Weight (kg)

- 1800 kg

- Computerized

- No

- Automatic

- No, Manual Operation

- CNC Or Not

- Not CNC (Manual)

- Control System

- Conventional manual controls

- Table Size

- 400 mm x 200 mm

- Table Slide Way

- V-flat guideways

- Magnetic Chuck Size

- 150 mm x 320 mm

- Grinding Wheel Size

- 100 mm to 250 mm diameter

- Grinding Wheel Speed

- Up to 24,000 rpm

- Grinding Length

- 250 mm

- Floor Space

- 1600 mm x 1200 mm

- Spindle Speed

- Up to 24,000 rpm (variable)

- Power

- 3.7 kW (5 HP)

- Voltage

- 415 V, 3 Phase, 50 Hz

- Dimension (L*W*H)

- 1600 mm x 1200 mm x 1700 mm

- Feature

- High accuracy, smooth operation, robust construction

- Color

- Machine Grey/Green

- Max Swing Over Table

- 400 mm

- Surface Finish Achievable

- Ra 0.2 µm

- Cross Table Travel

- 80 mm

- Internal Grinding Spindle Taper

- ISO 25

- Lubrication System

- Centralized manual lubrication

- Coolant System

- Integrated coolant tank and piping

- Longitudinal Table Travel

- 330 mm

- Working Speed

- Variable, up to 24,000 rpm

- Adjustable Workhead

- Yes, ±90°

- Chuck Type

- 3-jaw manual chuck (optional magnetic)

- Wheelhead Motor

- 3.7 kW

About Voumard Type 5A Internal Grinding Machine

Make - Voumard (Switzerland)

Model - 5A

Grinding Diameter - 5 mm to 200 mm

Center Height - 180 mm

Max. Swing Diameter of Job - 360 mm

Grinding Depth - 250 mm

Maximum Table Stroke - 600 mm

Spindle Speeds - 3,600 rpm to 40,000 rpm

Work-Head Speeds - 125 rpm to 1,000 rpm

Work-Head Swivel - 0 Degree to 90 Degree

- Equipped with Face Grinding Attachment.

- Equipped with Hydraulic Wheel-Dresser.

- Auto Cycle Working.

- Operating Manual & Electrical Drawings available.

- Machine is in excellent working condition.

Video link - https://youtu.be/uGv4jscQVwM

Robust Design for Precision Grinding

The Voumard Type 5A boasts a rugged cast iron/steel construction and V-flat guideways, delivering long-term durability and exceptional accuracy. Its adjustable workhead permits 90 movement, ensuring optimal alignment and repeatability for internal cylindrical grinding tasks required in high-precision manufacturing.

Flexible Manual Operation

This model operates with conventional manual controls, allowing skilled operators to fine-tune grinding parameters for unique applications. Its variable speed up to 24,000 rpm and adjustable components accommodate a wide range of workpiece sizes and materials, making it suitable for custom or batch production.

Efficient Cooling and Lubrication

Equipped with an integrated coolant tank and piping, the Voumard 5A manages heat effectively during high-speed grinding. Its centralized manual lubrication system supports smooth operation and reduces maintenance efforts, supporting consistent surface quality and extending component lifespan.

FAQs of Voumard Type 5A Internal Grinding Machine:

Q: How does the Voumard Type 5A achieve high-precision internal grinding?

A: The machine combines robust construction, V-flat guideways, variable spindle speeds up to 24,000 rpm, an adjustable workhead, and high-precision manual controls. These features facilitate accurate alignment and smooth, vibration-free grinding, resulting in superior surface finishes down to Ra 0.2 m.Q: What types of workpieces can be ground using this model?

A: The Voumard Type 5A is designed for internal cylindrical grinding of precision components with diameters ranging from 100 mm to 250 mm. It can accommodate varied materials such as steel or cast iron, suitable for exporters, importers, manufacturers, and suppliers working with high-accuracy requirements.Q: When is the integrated coolant system utilized during operation?

A: The integrated coolant system automatically manages thermal loads during high-speed or prolonged grinding sessions. By maintaining controlled temperatures, it helps prevent workpiece distortion and preserves surface integrity across different grinding applications.Q: Where is the Voumard Type 5A ideally installed?

A: With floor space requirement of 1600 mm x 1200 mm, the Voumard 5A is suited for shop floors in precision engineering companies, tool rooms, or manufacturing units in Swaziland and other locations. Its compact footprint aids in efficient workspace planning.Q: What is the process of adjusting the workhead and controls?

A: Operators can manually adjust the workhead within a 90 range to align the workpiece accurately. Conventional manual controls enable users to set grinding wheel speeds, table travel, and other parameters to match specific workpiece dimensions and grinding requirements.Q: Can the machine operate with a magnetic chuck, and what is the benefit?

A: Yes, the Voumard Type 5A offers an optional magnetic chuck (150 mm x 320 mm). Utilizing magnetic chucking enhances setup speed, especially for ferrous workpieces, and ensures secure holding, thereby reducing the risk of vibration and improving surface finish accuracy.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Internal Grinding Machine Category

Voumard 650 mm Diameter Internal Grinder Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Color : Other, Industrial green or blue

Automatic : Other, No, manual operation

Feature : Other, High precision, robust construction, suitable for heavy components

Spandau Lindner SJ-7 Internal Grinding Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Color : Other, Industrial Green/Grey

Automatic : No

Feature : Other, Precision Internal Grinding, Rigid Construction

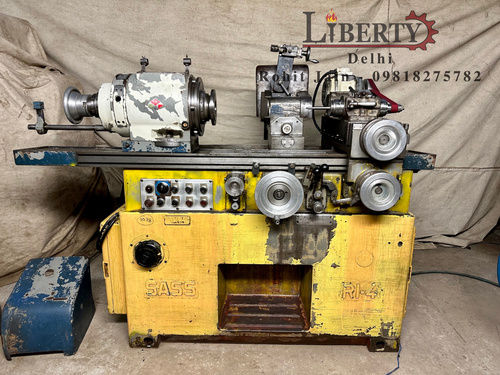

SASS Italy RI-4 Internal Grinder Machine

Price 25000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Color : Other, Industrial Grey

Automatic : Other, No, manual operation

Feature : Other, High accuracy, rigid construction, easy operation

Morara Internal Grinding Machine

Price 2000 EUR ()

Minimum Order Quantity : 1 Piece

Computerized : No

Color : Other, Blue & White

Automatic : No

Feature : Other, High accuracy, Durable construction

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry