Cantaluppi MC1100 Vertical Surface Grinder

Price 100000 INR/ Piece

Cantaluppi MC1100 Vertical Surface Grinder Specification

- Rotation

- Clockwise

- Model

- MC1100

- Product Type

- Vertical Surface Grinder

- General Use

- Vertical Surface Grinding

- Material

- Cast Iron, Steel

- Type

- Surface Grinder

- Capacity

- Heavy Duty

- Weight (kg)

- 2900 kg

- Computerized

- No

- Automatic

- No

- CNC Or Not

- Not CNC

- Control System

- Manual Control

- Table Size

- 1100 mm x 300 mm

- Table Slide Way

- Precision Slideways

- Magnetic Chuck Size

- 1100 mm

- Grinding Wheel Size

- 350 mm x 100 mm

- Grinding Wheel Speed

- 1450 RPM

- Grinding Length

- 1100 mm

- Floor Space

- 2500 mm x 1900 mm

- Fuel Tank Capacity

- 80 L

- Spindle Speed

- 1450 RPM

- Power

- 7.5 kW

- Voltage

- 415 V

- Dimension (L*W*H)

- 2500 mm x 1900 mm x 2100 mm

- Feature

- High Precision, Robust Design

- Color

- Green

- Installation Time

- 3 Hours

- Coolant System

- Integrated Coolant System

- Working Speed

- Adjustable

- Chuck Type

- Electro-Magnetic

- Table Traverse

- Hydraulic / Manual

- Noise Level

- < 75 dB

- Max Distance Between Table & Spindle

- 550 mm

- Lubrication Type

- Centralized Lubrication

- Maximum Table Load

- 700 kg

- Packing Type

- Wooden Box

- Minimum Grinding Thickness

- 1 mm

- Grinding Wheel Motor

- 7.5 HP

Cantaluppi MC1100 Vertical Surface Grinder Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About Cantaluppi MC1100 Vertical Surface Grinder

Make - Cantaluppi (Italy)

Model - MC1100

Max. Job Size - 375 mm x 1200 mm

Table Size - 260 mm x 1000 mm

Current Magnet Size - 120 mm x 1200 mm

Segmented Cup Wheel Diameter - 205 mm

No. of Segments in Wheel - 6 pcs.

Max. Distance between Table to Wheel - 400 mm

Spindle Motor - 5.2 kW

- Motorised Rapid Vertical Travel of the Wheel-Head.

- Equipped with a Wheel Dresser.

- Machine is in excellent working condition.

Video of The Machie -

Built for Precision and Durability

The MC1100 features high-quality construction with a heavy-duty, robust design, ideal for handling demanding surface grinding applications. The precision slideways, electro-magnetic chuck, and integrated coolant system all work together to ensure smooth operation and accurate results on various metals.

Efficient and User-Friendly Operation

Designed for operator convenience, the grinder incorporates adjustable working speeds and both hydraulic and manual table traverse. Centralized lubrication and a wooden box packaging option facilitate both maintenance and transportation, while a low noise level of under 75 dB ensures a comfortable working environment.

Applications Across Industries

This Italian-made grinder is not computerized but excels in manual, high-precision surface grinding. Suitable for exporters, manufacturers, and suppliers, it provides reliable results for industries that require sustained accuracy and durability in their grinding processes.

FAQs of Cantaluppi MC1100 Vertical Surface Grinder:

Q: How does the integrated coolant system benefit the grinding process?

A: The integrated coolant system ensures continuous cooling of the grinding area, reducing heat buildup, preventing distortion, and increasing the lifespan of both the grinding wheel and workpieces. This helps maintain high precision during extended grinding sessions.Q: What materials can be processed on the Cantaluppi MC1100 Surface Grinder?

A: This machine is designed to handle a range of materials, primarily cast iron and steel. Its robust construction and high-capacity chuck make it suitable for heavy-duty industrial applications involving these metals.Q: When is the Cantaluppi MC1100 an ideal choice for manufacturers?

A: The MC1100 is ideal for manufacturers requiring accurate surface finishes on large, heavy workpieces. Its high table load capacity, precision mechanics, and manual control are well-suited for specialized and high-volume grinding operations where CNC automation isnt needed.Q: Where can the MC1100 Surface Grinder be installed and operated efficiently?

A: With floor space requirements of 2500 mm x 1900 mm and straightforward three-hour installation, the MC1100 is suitable for industrial workshops and factories prioritizing precision surface grinding. Its robust packing in a wooden box supports safe transportation and placement within such settings.Q: What is the process of adjusting the working speed on this grinder?

A: Working speed is adjustable via manual controls, allowing the operator to tailor the grinding action according to the material and required surface finish. This flexibility enhances process control and ensures optimal results for different workpieces.Q: How does the centralized lubrication system contribute to machine longevity?

A: Centralized lubrication ensures all key components receive consistent and adequate lubrication, reducing wear and maintenance needs. This prolongs the service life of precision parts and sustains the grinders performance over time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Surface Grinder Category

Jakobsen High Precision Surface Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

CNC Or Not : Other, Not CNC

Automatic : No

Control System : Manual

Product Type : Surface Grinder

TOS 200 mm x 600 mm Surface Grinding Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

CNC Or Not : Other, Not CNC

Automatic : No

Control System : Manual

Product Type : Surface Grinding Machine

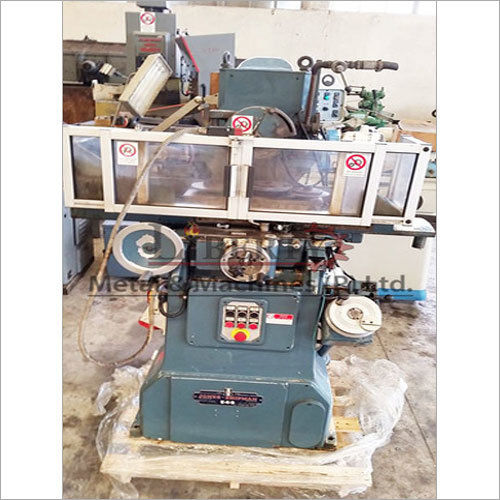

Jones Shipman Hydraulic Surface Grinder

Price 4800 INR / Piece

Minimum Order Quantity : 1 Piece

CNC Or Not : Not CNC, Other

Automatic : No

Control System : Hydraulic, Other

Product Type : Jones Shipman Hydraulic Surface Grinder

Jones & Shipman 540 Surface Grinder

CNC Or Not : Other, Not CNC

Automatic : No

Control System : Manual

Product Type : Surface grinder

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry