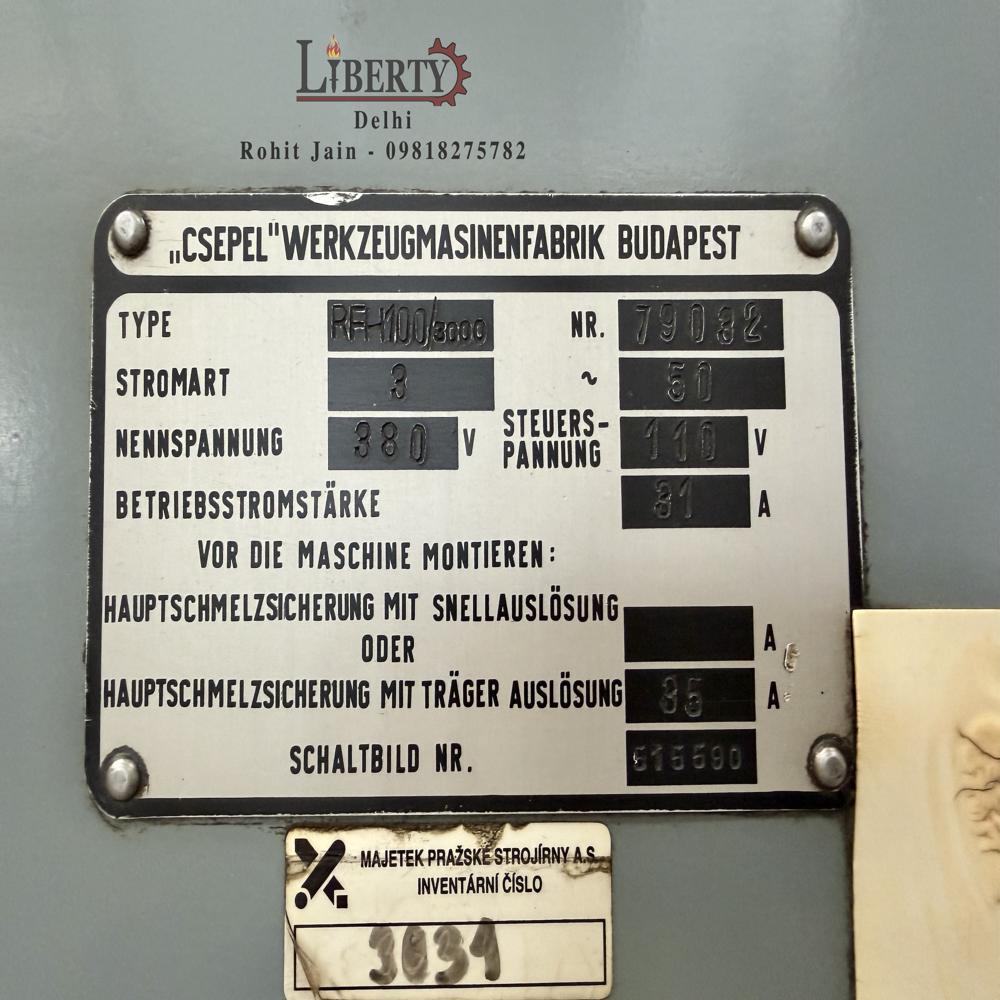

Csepel Hungary RFH-100/3000 Heavy Duty Radial Drilling Machine

Price 100000.0 INR/ Piece

Csepel Hungary RFH-100/3000 Heavy Duty Radial Drilling Machine Specification

- Features

- Hydraulic & mechanical clamping, robust construction, large arm travel, adjustable drill head

- Diameter

- Max. drilling diameter 100 mm

- Noise Level

- Within standard industrial limits

- Dimension (L*W*H)

- 4250 mm x 1550 mm x 3800 mm

- Cutting Area

- Large, for oversized workpieces

- Table Size

- 1000 mm x 800 mm (approx.)

- Frequency

- 50 Hz

- Condition

- Excellent Working Condition

- Machine Type

- Radial Drilling Machine

- Spindle Speed

- 16 steps, 22 1120 RPM

- Motor Power

- 7.5 kW (Main Drive)

- Product Type

- Csepel (Hungary) make Heavy Duty Radial Drilling Machine in excellent working condition. The model of the machine is RFH-100/3000. The Drilling Capacity of the Machine is 100 mm and the Arm Length is 3100 mm. The technical details are as follows -

- Material

- Cast Iron/Heavy Duty Steel

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- CNC Or Not

- No

- Control System

- Manual

- Voltage

- 415 V (Three Phase)

- Power

- 10 HP

- Power Source

- Electric

- Weight (kg)

- Approx. 9000 kg

- Capacity

- Drilling 100 mm

- Color

- Industrial Grey/Green (subject to availability)

- Usage & Applications

- Heavy-duty drilling, boring & tapping in fabrication, steel plants & machinery workshops

- Column Diameter

- 520 mm

- Spindle Speeds & Feeds

- 16 speeds, 22 to 1120 rpm; 16 feeds, 0.044 3.15 mm/rev

- Spindle Travel

- 400 mm

- Drilling Capacity (Steel)

- 100 mm

- Minimum Drilling Radius

- 700 mm

- Spindle Taper

- Morse Taper No. 6

- Coolant System

- Available

- Built-in Safety Features

- Overload protection, emergency stop switch

- Vertical Travel of Arm

- 1050 mm

- Base Plate Size

- 2510 mm x 1310 mm

- Maximum Drilling Radius

- 3155 mm

- Make & Model

- Csepel RFH-100/3000 (Hungary)

- Arm Length

- 3100 mm

- Distance Spindle to Base Plate

- 350 1400 mm

About Csepel Hungary RFH-100/3000 Heavy Duty Radial Drilling Machine

Heavy-Duty Performance for Industrial Demands

With a substantial drilling capacity of 100 mm and the ability to handle oversized workpieces, the Csepel RFH-100/3000 stands out in fabrication shops, steel plants, and machinery workshops. Its robust construction, generous arm travel, and adjustable drill head ensure versatility and reliability in a range of heavy-duty applications.

Precision, Safety, and Versatility

The machine is built with hydraulic and mechanical clamping mechanisms for precise operations. Overload protection and an emergency stop provide critical safety, while a broad range of speeds and feeds allows adaptation to various materials and requirements. The integrated coolant system ensures smooth and efficient drilling even during demanding tasks.

FAQ's of Csepel Hungary RFH-100/3000 Heavy Duty Radial Drilling Machine:

Q: How can the Csepel RFH-100/3000 radial drilling machine be used in industrial workshops?

A: This radial drilling machine is designed for heavy-duty drilling, boring, and tapping tasks. With its high-capacity arm and broad working radius, it is ideal for large-scale fabrication, steel plant operations, and maintenance work in machinery workshops.Q: What are the key benefits of the machine's hydraulic and mechanical clamping system?

A: The combination of hydraulic and mechanical clamping ensures stable and secure operation of the drill head and arm, contributing to accurate hole placement and minimizing vibration during machining processes.Q: When is it necessary to use the maximum spindle travel and arm length?

A: Maximum spindle travel (400 mm) and long arm reach (3100 mm) are crucial when working with oversized or thick workpieces, allowing for deeper drilling and versatile positioning without the need to reposition the workpiece frequently.Q: Where should the Csepel RFH-100/3000 be installed for optimal usage?

A: It is best suited for spacious industrial environments such as large fabrication shops, steel manufacturing plants, or workshops where handling large and heavy workpieces is routine. Adequate floor space is required to accommodate its size and facilitate movement.Q: What safety features are included with this drilling machine?

A: Safety features include overload protection, which prevents the machine from operating under excessive load, and an emergency stop switch to immediately halt operation if needed, ensuring operator safety.Q: How does the machine's coolant system improve the drilling process?

A: The built-in coolant system helps dissipate heat generated during drilling, extending tool life, ensuring smoother cutting, and reducing material deformation, especially during prolonged heavy-duty operations.Q: What is the process for adjusting spindle speed and feed rate on this model?

A: The Csepel RFH-100/3000 features manual controls for selecting from 16 spindle speeds (22-1120 rpm) and 16 feed rates (0.044-3.15 mm/rev). Operators can easily adjust these settings to match the material and drilling requirements of each job.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Radial Drilling Machine Category

GSP France Automatic Drilling and Tapping Machine

Price 45000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : Yes

CNC Or Not : CNC

Control System : PLC Control

Material : Cast Iron, Stainless Steel

Webo 60 mm Capacity Pillar Drilling Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

CNC Or Not : Other, No

Control System : Other, Manual

Material : Heavy Duty Cast Iron Body

Breda 40 mm Capacity Radial Drilling Machine

Price 12000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

CNC Or Not : Other, No

Control System : Other, Lever & Gear

Material : Highgrade Cast Iron

MAS 35 mm Radial Drilling Machine

Price 25000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

CNC Or Not : Other, No

Control System : Other, Manual

Material : Heavyduty Cast Iron, Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry