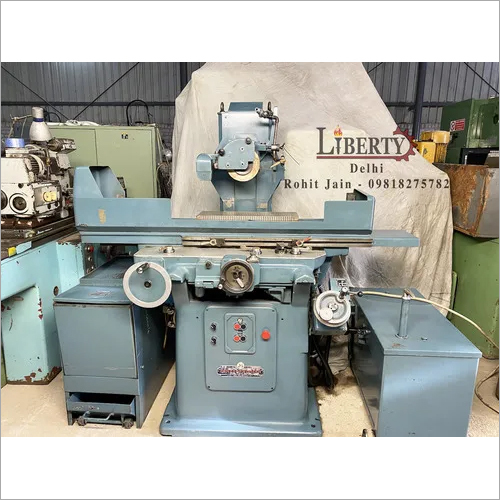

ELB 200 x 450 Precision Surface Grinder

Price 100000 INR/ Piece

ELB 200 x 450 Precision Surface Grinder Specification

- Model

- ELB 200 x 450

- Rotation

- Wheel Rotation Clockwise

- Product Type

- Precision Surface Grinder

- General Use

- Precision Surface Grinding

- Material

- Cast Iron Body with Hardened Steel Parts

- Type

- Horizontal Surface Grinder

- Capacity

- Max. Grinding Area 200 x 450 mm

- Weight (kg)

- Approx. 1200 kg

- Computerized

- No

- Automatic

- No

- CNC Or Not

- Not CNC

- Control System

- Manual

- Table Size

- 200 x 450 mm

- Table Slide Way

- V and Flat Guideways

- Magnetic Chuck Size

- 200 x 450 mm

- Grinding Wheel Size

- 200 x 13 x 31.75 mm

- Grinding Wheel Speed

- 2850 RPM

- Grinding Length

- 450 mm

- Floor Space

- 1500 x 1200 mm

- Fuel Tank Capacity

- Approx. 35 Liters

- Spindle Speed

- 2850 RPM

- Power

- 1.5 HP

- Voltage

- 415 V, 3 Phase

- Dimension (L*W*H)

- 1500 x 1200 x 1700 mm

- Feature

- Dust Collector Attachment, Easy Operation, Precision Ground Table

- Color

- Standard Grey / Blue

- Lubrication System

- Centralized Automatic Lubrication

- Table Longitudinal Travel

- 500 mm

- Maximum Distance From Table Surface To Spindle Centre

- 350 mm

- Coolant Pump Power

- 0.12 HP

- Table Load Capacity

- Max. 120 kg

- Working Speed

- 0.5 - 20 m/min

- Surface Finish Achievable

- Below Ra 0.3 µm

- Hand Feed Graduation

- Cross - 0.02 mm, Vertical - 0.005 mm

- Spindle Motor Power

- 1.5 HP (1.1 kW)

- Table Cross Travel

- 210 mm

- Hydraulic Motor Power

- 0.75 HP (0.55 kW)

- Chuck Mounting Type

- Electromagnetic or Permanent Magnetic (Optional)

ELB 200 x 450 Precision Surface Grinder Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About ELB 200 x 450 Precision Surface Grinder

Make - ELB (Germany)

Model - SW4HA

Capacity - 200 mm x 450 mm

Grinding Wheel Diameter - 250 mm

Grinding Wheel Width - 25 mm

Longitudinal Travel - 500 mm

Cross Travel - 250 mm

Max. Height between Table to Wheel Center - 550 mm

Current Magnet Size - 160 mm x 400 mm

- Micro-Feed Travels in both Vertical & Cross Travels.

- It is a Column Moving type Design of Surface Grinder.

- Complete with Coolant Tank and Pump.

- Machine is in excellent working condition.

Video of The Machine -

Superior Surface Finishing

Achieve highly refined results with a surface finish below Ra 0.3 m. The ELB 200 x 450's robust spindle and precision-ground table, driven by a 1.5 HP motor and guided by V and flat slideways, ensure uniform grinding over the entire 200 x 450 mm area. This makes it perfect for applications requiring tight tolerances and smooth surfaces.

Reliable and Versatile Performance

Designed for consistent operation, this surface grinder features both electromagnetic and permanent magnetic chuck options, adapting to different workpiece requirements. The centralized automatic lubrication system and dust collector attachment contribute to low maintenance needs and a cleaner workspace, making the ELB 200 x 450 a reliable machine for daily use.

FAQ's of ELB 200 x 450 Precision Surface Grinder:

Q: How does the ELB 200 x 450 Precision Surface Grinder achieve such fine surface finishes?

A: The ELB 200 x 450 is designed with a high-quality grinding wheel rotating at 2850 RPM and a sturdy construction that minimizes vibrations, ensuring even grinding. The precision-ground table and V and flat guideways, along with centralized automatic lubrication, further aid in delivering a surface finish below Ra 0.3 m.Q: What types of workpieces can be handled and how much weight can the table support?

A: This grinder can accommodate various flat workpieces for precision grinding, with a maximum table load capacity of 120 kg. Both magnetic chucks-electromagnetic and permanent magnetic-are available, enabling secure clamping and adaptability for ferrous materials.Q: When should maintenance be performed and what are the key maintenance features?

A: Routine checks should be conducted to ensure optimal performance, focusing on the lubrication system and grinding wheel integrity. The ELB 200 x 450 features a centralized automatic lubrication system, which reduces manual upkeep and ensures smooth long-term operation.Q: Where is the ELB 200 x 450 Precision Surface Grinder most effectively used?

A: This model is widely employed in tool rooms, manufacturing plants, and metalworking shops requiring precise surface finishing. Its rugged build and high accuracy make it suitable for industrial applications demanding consistent, high-quality grinding.Q: What is the process involved in using this surface grinder for high precision work?

A: Operation involves securely mounting the workpiece to the magnetic chuck, setting table movements with manual controls, and adjusting feed rates according to the material and finish requirements. The coolant and lubrication systems minimize heat and ensure precision throughout the grinding process.Q: What benefits does the ELB 200 x 450 offer over conventional surface grinders?

A: Key advantages include its high-precision capabilities, low maintenance owing to automated lubrication, dust collector attachment for cleaner operation, and adaptability with multiple chuck types. Its manual control system provides the operator with tactile feedback for intricate tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Surface Grinder Category

Jotes SAB-100W Vertical Rotary Surface Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Feature : Other, Heavy duty, robust construction, high precision grinding

Automatic : No

CNC Or Not : Other, No (Manual Machine)

Cantaluppi MC1100 Vertical Surface Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Feature : Other, High Precision, Robust Design

Automatic : No

CNC Or Not : Other, Not CNC

Jones & Shipman Surface Grinder Machine

Price 3750 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Feature : Other, Surface Grinding

Automatic : No

CNC Or Not : Not CNC, Other

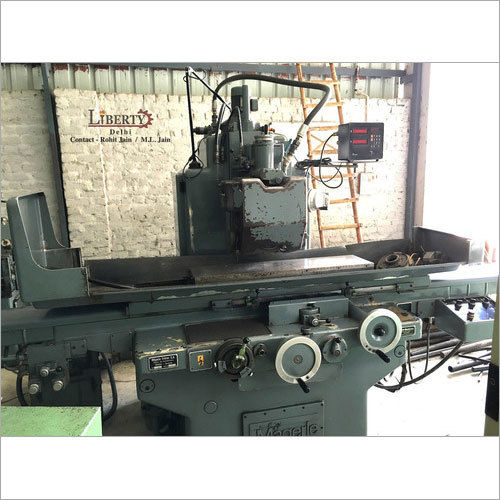

Magerle Creep Feed Surface Grinder

Computerized : Yes

Feature : High Precision Grinding, Other

Automatic : Yes

CNC Or Not : Other, Yes

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry