Magerle Creep Feed Surface Grinder

Magerle Creep Feed Surface Grinder Specification

- Product Type

- Surface Grinder

- General Use

- Surface Grinding

- Material

- Cast Iron/Stainless Steel

- Type

- Creep Feed

- Computerized

- Yes

- Automatic

- Yes

- CNC Or Not

- Yes

- Control System

- Manual and CNC

- Table Size

- Standard

- Magnetic Chuck Size

- Standard

- Grinding Wheel Size

- Standard

- Feature

- High Precision Grinding

- Color

- Grey

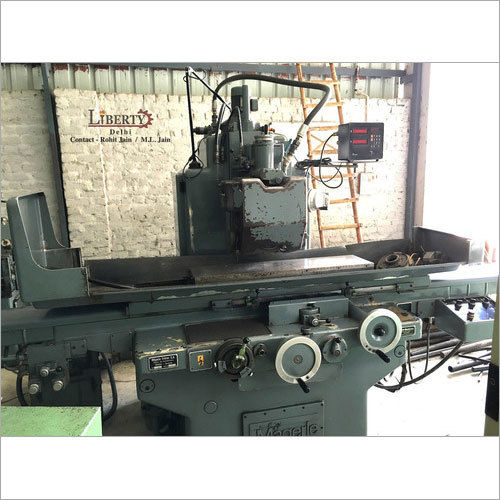

About Magerle Creep Feed Surface Grinder

Creep Feed Surface Grinder

Make - Magerle (Switzerland)

Model - F10

Grinding Width 300 mm

Grinding Length 1000 mm

Longitudinal Travel 1130 mm

Table Cross Travel 270 mm

Magnet Size 250 mm x 1000 mm

Working Table 240 mm x 1050 mm

Automatic depth adjustment 0.001 mm to 0.012 mm

Grinding Wheel Size Diameter 300 mm x 127 mm (Bore)

- With Automatic Depth Adjustment Auto-cut

- With Creep Feed Grinding facility.

- complete with DRO, coolant filtration unit etc.

Unmatched Precision for Surface Grinding

The Magerle Creep Feed Surface Grinder is designed for applications where both reliability and accuracy are critical. Built with a focus on high precision, it efficiently processes cast iron and stainless steel components, making it ideal for industries requiring close tolerances. Its robust frame and dependable Swiss engineering ensure top-tier results in every operation.

Flexible Automation and Controls

This machine seamlessly bridges manual and computerized CNC operation, offering users maximum flexibility. Automated features minimize operator workload, while intuitive interfaces ensure straightforward programming and setup. Its adaptability makes it suitable for varying production requirements, from prototyping to high-volume manufacturing.

FAQs of Magerle Creep Feed Surface Grinder:

Q: How does the Magerle Creep Feed Surface Grinder achieve high precision during operation?

A: The Magerle grinder utilizes advanced CNC controls and precise mechanical components to maintain tight tolerances throughout grinding cycles. Its rigid structure reduces vibration, while specialized feed systems enable consistent, accurate material removal on cast iron or stainless steel parts.Q: What materials can be processed using this surface grinder?

A: This grinder is engineered to handle a variety of metals, with optimized performance when working with cast iron and stainless steel. Its robust build and adaptable grinding parameters allow for efficient processing of both soft and hard materials.Q: When should I choose a creep feed surface grinder over other grinding machines?

A: A creep feed surface grinder like the Magerle is ideal when you require deep cuts with high material removal rates while maintaining surface integrity and precision. It is particularly beneficial for complex, high-stress components or when efficiency and surface finish are priorities.Q: Where can this grinder be used within a manufacturing facility?

A: Due to its flexibility and efficiency, it can be installed in tool rooms, production lines, or finishing departments where surface preparation of cast iron or stainless steel is required. Its standard table and chuck sizes allow easy integration into most industrial layouts.Q: What is the process involved in operating this grinder with CNC and manual controls?

A: Users can operate the grinder manually for one-off jobs or program CNC cycles for repeat or intricate grinding tasks. The computerized system ensures consistency, while manual overrides allow skilled operators to make adjustments for specialized parts or processes.Q: How can using this grinder benefit my production workflow?

A: Employing this automatic, precision grinder improves surface finish, reduces processing times, and enhances repeatability. Its versatility in materials and controls supports both custom and mass production, maximizing productivity and minimizing equipment downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Surface Grinder Category

G. Rastelli 300 mm x 600 mm Surface Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

CNC Or Not : Other, Not CNC

Feature : Other, Precision Surface Finish, HeavyDuty Construction

Automatic : No

Alpa RT 800 Surface Grinding Machine

Price 6000 INR

Minimum Order Quantity : 1 Piece

Computerized : No

CNC Or Not : Other, No

Feature : Other, Sturdy Structure, High Accuracy, Efficient Performance

Automatic : No

MAS 300 x 1000 Cup Grinder

Price 7600 INR

Minimum Order Quantity : 1 Piece

Computerized : No

CNC Or Not : Other, No

Feature : Other, High Precision, Rigid Structure, Versatile Application

Automatic : No

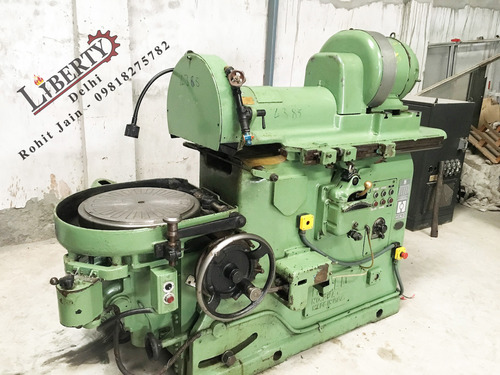

Rotary Surface Grinder

Minimum Order Quantity : 1 Piece

Computerized : No

CNC Or Not : No, Other

Feature : Other, Rotary table with magnetic chuck

Automatic : Yes

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry