Fortuna Internal Grinding Machine

Fortuna Internal Grinding Machine Specification

- Rotation

- Both Clockwise and Counter-Clockwise

- Model

- Fortuna Internal Grinding Machine

- Product Type

- Internal Grinding Machine

- General Use

- Internal grinding operations for precision engineering and toolroom works

- Material

- Cast Iron, Sheet Metal, and Alloy Steel

- Type

- Internal cylindrical grinder

- Capacity

- 1 piece at a time

- Weight (kg)

- Approx. 1400 kg

- Computerized

- No

- Automatic

- No

- CNC Or Not

- No, Conventional

- Control System

- Manual

- Table Size

- 340 x 180 mm

- Table Slide Way

- V and Flat Type

- Magnetic Chuck Size

- 150 mm

- Grinding Wheel Size

- 200 mm diameter

- Grinding Wheel Speed

- Up to 2880 RPM

- Grinding Length

- 125 mm

- Floor Space

- 1400 x 1100 mm

- Spindle Speed

- 2800 RPM

- Power

- 2 HP

- Voltage

- 415 V, 3 Phase

- Dimension (L*W*H)

- Approx. 1400 x 1100 x 1500 mm

- Feature

- High precision, robust construction, smooth operation

- Color

- White & Blue

- Max Workpiece Length

- 125 mm

- Lubrication System

- Centralized lubrication

- Bore Grinding Capacity

- 6 mm to 100 mm

- Surface Finish Ra

- 0.2 µm

- Dressers

- Single point diamond dresser

- Main Motor Power

- 1.5 kW

- Accuracy

- 0.002 mm

- Work Head Speeds

- Variable, up to 250 RPM

- Chuck Type

- Manual 3-jaw chuck

- Max Workpiece Diameter

- 125 mm

- Quill Stroke

- 70 mm

- Coolant System

- Inbuilt pump with recirculation

About Fortuna Internal Grinding Machine

Make - Fortuna (Germany)

Max. Diameter of Job - 380 mm

Max. Ground-able Internal Diameter - 250 mm

Table Longitudinal Travel - 300 mm

Chuck Diameter - 160 mm

Face Grinding Wheel Diameter - 175 mm

Internal Grinding Spindle Diameter (2 pcs) - 80 mm & 60 mm

Work-Head Rotation Angle - 20o to -10o

- Machine is equipped with DRO

- Automatic Depth Adjustment "Auto-Cut"

- Complete with wheel dresser, reverse jaw set for chuck, spare spindle, belts etc.

- Complete with Coolant pump etc.

- Machine is in excellent working condition.

https://youtu.be/NAa6xkK93V0

Robust Construction and Precision

Constructed from high-grade cast iron, sheet metal, and alloy steel, the Fortuna Internal Grinding Machine is built for durability and stability. Its rigid structure supports high-accuracy operations, maintaining precision to 0.002 mm. This makes it an excellent choice for toolrooms and heavy-duty precision engineering requirements where reliability and meticulous finishing are paramount.

Flexible Operation and User Control

Equipped with a manual 3-jaw chuck and variable work head speeds up to 250 RPM, the machine accommodates a range of workpiece sizes and materials. Operators benefit from manual control, allowing flexible and customized adjustment for different internal grinding tasks. Both clockwise and counterclockwise rotation extend its versatility for specialized operations.

Advanced Cooling and Lubrication Systems

The integrated recirculating coolant pump ensures effective grinding wheel cooling, preventing overheating and preserving workpiece integrity. A centralized lubrication system delivers oil precisely where needed, reducing wear and extending the lifespan of critical components for consistent performance over time.

FAQs of Fortuna Internal Grinding Machine:

Q: How does the Fortuna Internal Grinding Machine ensure high-precision grinding operations?

A: The machine is engineered with robust cast iron construction and precise manual control, achieving a grinding accuracy of 0.002 mm. Its rigid table slide with V and flat ways and variable work head speeds further enhance process stability and finish quality.Q: What is the process for operating the machine with the manual 3-jaw chuck?

A: Simply mount the workpiece within the 3-jaw chuck manually, adjust the work head speed as needed (up to 250 RPM), and guide the grinding operation through the manual controls to achieve internal finishes according to your specifications.Q: When should the centralized lubrication system be used?

A: The centralized lubrication system operates automatically during machine use, ensuring all moving parts receive proper lubrication continuously, which is critical during prolonged operations or high-precision jobs.Q: Where is this grinding machine best utilized?

A: The Fortuna Internal Grinding Machine is ideally used in precision engineering workshops, toolrooms, and manufacturing facilities that require internal cylindrical grinding for small-batch or single workpieces, particularly in tool and die making, repair, and component finishing.Q: What materials can be ground using this machine?

A: Thanks to its solid build and powerful 1.5 kW main motor, the machine is suitable for grinding a variety of metals such as hardened steels, cast iron, and alloy components within its 6 mm to 100 mm bore capacity and 125 mm workpiece size limit.Q: How does the coolant system benefit the grinding process?

A: The inbuilt recirculation pump provides a steady stream of coolant to the work area, minimizing thermal deformation, reducing wheel wear, and effectively removing debris for superior surface finish and dimensional accuracy.Q: What advantages does manual control offer over CNC models?

A: Manual operation allows skilled users to adjust settings in real time, catering to complex or one-off grinding tasks with greater flexibility, making the machine particularly valuable in toolrooms and where adaptability is essential.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Internal Grinding Machine Category

Spandau Lindner SJ-7 Internal Grinding Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : No

Color : Other, Industrial Green/Grey

Computerized : No

Feature : Other, Precision Internal Grinding, Rigid Construction

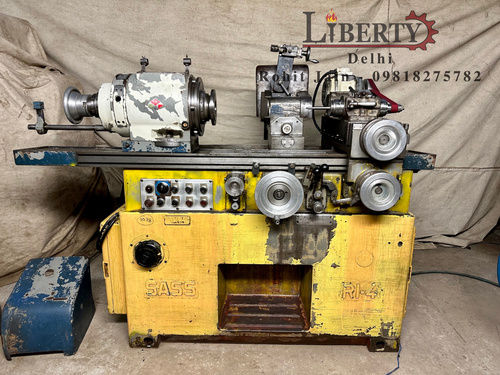

SASS Italy RI-4 Internal Grinder Machine

Price 25000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : Other, No, manual operation

Color : Other, Industrial Grey

Computerized : No

Feature : Other, High accuracy, rigid construction, easy operation

Voumard Type 5A Internal Grinding Machine

Price 60000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : Other, No, Manual Operation

Color : Other, Machine Grey/Green

Computerized : No

Feature : Other, High accuracy, smooth operation, robust construction

Kikinda Yugoslavia 584 mm Dia Internal Grinding Machine

Price 100000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : No

Color : Other, Industrial Grey

Computerized : No

Feature : Other, Heavy Duty, robust construction, reliable operation

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry