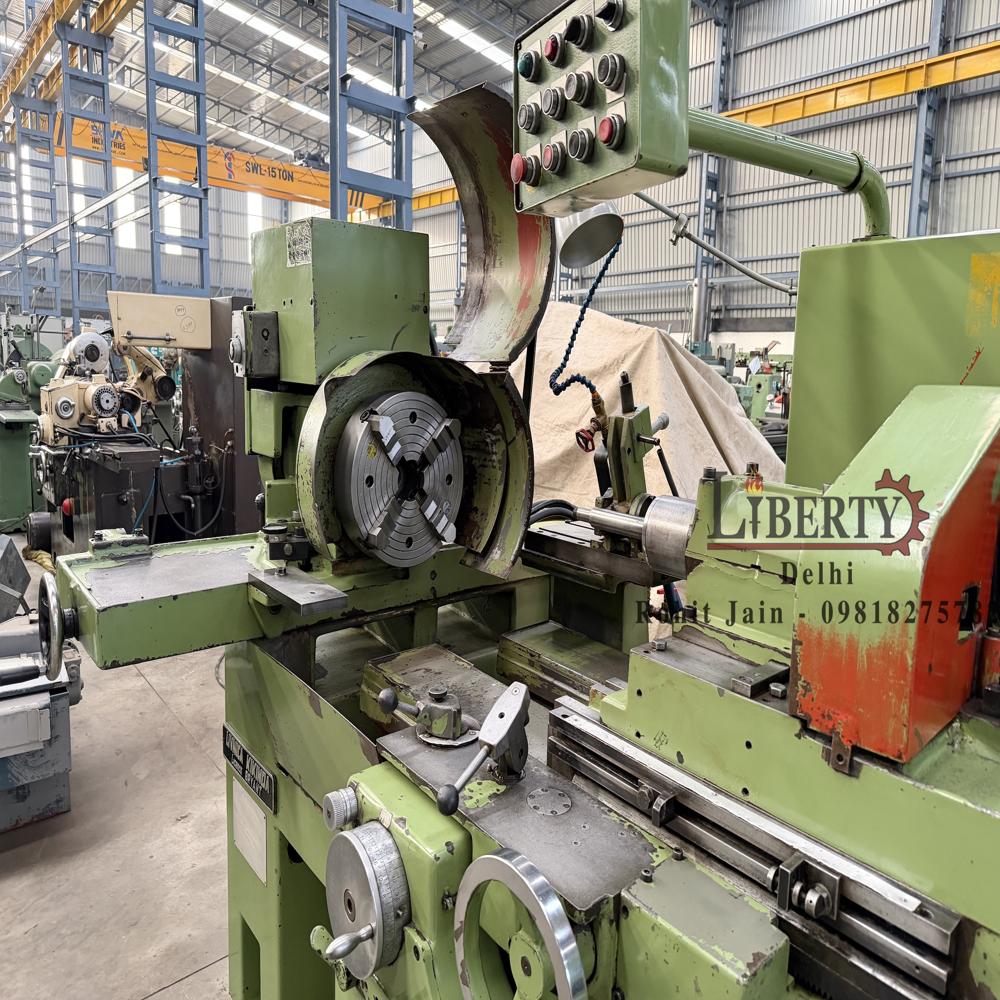

Kikinda Yugoslavia 584 mm Dia Internal Grinding Machine

Price 100000.0 INR/ Piece

Kikinda Yugoslavia 584 mm Dia Internal Grinding Machine Specification

- Rotation

- Job rotation and spindle rotation both available

- Model

- Universal

- Product Type

- Internal Grinding Machine

- General Use

- Kikinda (Yugoslavia) make Heavy Duty Internal Grinding Machine in excellent working condition. The machine has been made under the license of Bryant (USA). The model of the machine is "Universal" and the Maximum Job Swing Diameter is 584 mm (23"). The technical details are as follows -

- Material

- Heavy Duty Cast Iron

- Type

- Universal

- Capacity

- Max. Swing Diameter 584 mm

- Weight (kg)

- Approx. 5 Tons

- Computerized

- No

- Automatic

- No

- CNC Or Not

- Not CNC

- Control System

- Conventional / Manual

- Table Slide Way

- Vee and Flat guideways

- Spindle Speed

- Variable, up to 1200 rpm

- Voltage

- 3 Phase, 415 V

- Feature

- Heavy Duty, robust construction, reliable operation

- Color

- Industrial Grey

- Chuck Type

- Hydraulic/Manual

- Condition

- Excellent working condition

- Machine Brand

- Kikinda

- Max Swing Diameter

- 584 mm (23 inches)

- Machine Base

- Monolithic, vibration-damping structure

- Lubrication System

- Centralized automatic lubrication

- Application

- Precision Internal Grinding for heavy duty components

- Feed System

- Manual and hydraulic options

- Licensed By

- Bryant (USA)

- Coolant System

- Integrated coolant system (standard)

- Minimum Internal Bore Grinding

- Approx. 30 mm

About Kikinda Yugoslavia 584 mm Dia Internal Grinding Machine

Engineered for Heavy-Duty Precision

Built with a monolithic, vibration-damping structure and a heavyweight cast iron base, this internal grinding machine delivers consistent precision in grinding large, heavy components. Its robust construction ensures long-term durability while supporting high machining accuracy for industrial applications.

Versatile and Reliable Operation

With both manual and hydraulic feed systems, variable spindle speeds up to 1200 rpm, and options for hydraulic and manual chuck types, this machine is adaptable to a wide range of grinding requirements. The integrated coolant and centralized automatic lubrication keep performance high and maintenance low.

Designed for Industrial Environments

This universal model is suitable for exporters, importers, manufacturers, suppliers, and traders in India. Its job and spindle rotation options, coupled with a maximum swing diameter of 584 mm, make it ideal for precision internal grinding in heavy engineering sectors.

FAQ's of Kikinda Yugoslavia 584 mm Dia Internal Grinding Machine:

Q: How does the Kikinda 584 mm Internal Grinding Machine enhance precision for heavy-duty components?

A: The machine is built on a monolithic, vibration-damping cast iron structure that minimizes deflection during operation, ensuring high-precision grinding of large, heavy parts. Its advanced features, such as variable spindle speed and centralized lubrication, support consistent and accurate results.Q: What types of internal grinding tasks can this machine handle?

A: This universal model is engineered for precision internal grinding of heavy and oversized components, accommodating internal bores as small as approximately 30 mm and providing a maximum swing diameter of 584 mm (23 inches). It suits industries such as automotive, aerospace, and heavy machinery.Q: When should I use the hydraulic versus the manual feed or chuck options?

A: Hydraulic feed and chuck are ideal for repetitive, high-volume or heavy workloads requiring steady force and reduced operator fatigue. Manual options allow for more operator control during small-batch jobs or intricate workpieces needing special attention.Q: Where is the Kikinda 584 mm Grinding Machine commonly supplied or used?

A: This industrial grinder is widely utilized by exporters, importers, manufacturers, suppliers, and traders in India. Its heavy-duty nature makes it suitable for workshops and factories engaged in fabricating or repairing large mechanical and engineering components.Q: What is the process for maintaining the machine's performance?

A: The machine features a centralized automatic lubrication system to ensure all moving parts are properly oiled, reducing downtime and wear. Regular checks on the coolant system and mechanical alignments further sustain optimal performance.Q: How does the integrated coolant system benefit the grinding operation?

A: The integrated coolant system efficiently manages heat generation during the grinding process, preventing workpiece distortion, enhancing surface finish, and extending both tool and machine life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Internal Grinding Machine Category

Tripet MAR 200 Precision Internal Grinder

Price 45000 INR / Piece

Minimum Order Quantity : 1 Piece

Grinding Wheel Size : 250 mm x 25 mm

Type : Other, Vertical/Horizontal Internal Grinding

Grinding Length : 200 mm

Spindle Speed : Variable, up to 60,000 rpm

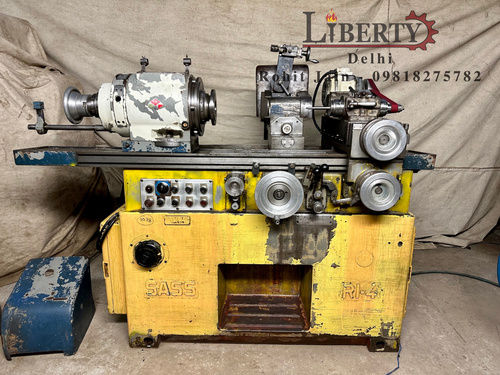

SASS Italy RI-4 Internal Grinder Machine

Price 25000 INR / Piece

Minimum Order Quantity : 1 Piece

Grinding Wheel Size : 100 x 50 x 20 mm

Type : Other, Precision Grinder

Grinding Length : 100 mm

Spindle Speed : 13,500 rpm

WMW SI 400 x 500 Heavy Duty Internal Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Grinding Wheel Size : 400 mm

Type : Other, Heavy Duty Industrial

Grinding Length : 500 mm

Spindle Speed : Variable, up to 1200 rpm

Morara Internal Grinding Machine

Price 2000 EUR ()

Minimum Order Quantity : 1 Piece

Grinding Wheel Size : 250 mm

Type : Other, Vertical

Grinding Length : 150 mm

Spindle Speed : 2003000 RPM (Variable)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry