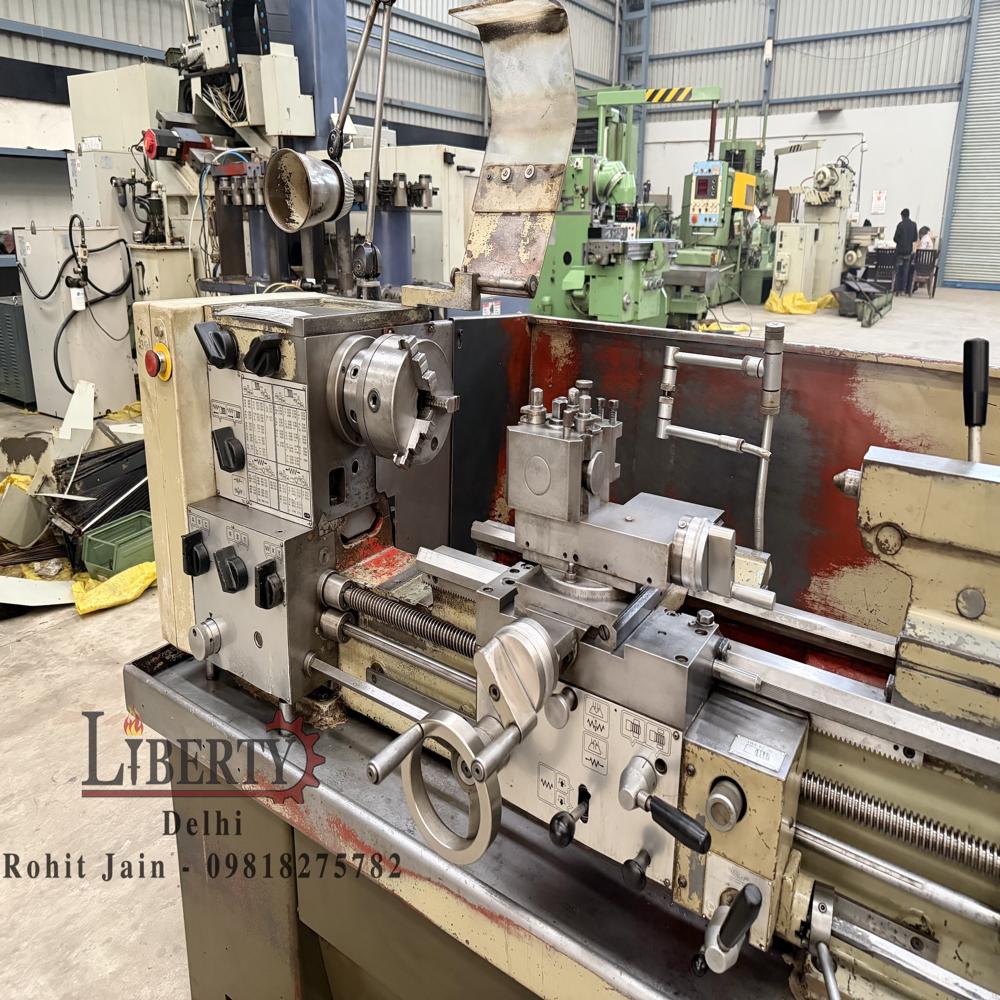

Harrison England M300 x 635 mm Length Gap-Bed Lathe Machine

Price 100000.0 INR/ Piece

Harrison England M300 x 635 mm Length Gap-Bed Lathe Machine Specification

- Product Type

- Gap-Bed Lathe Machine

- Material

- Harrison (England) make Gap-Bed type Lathe Machine in excellent working condition. The model of the machine is M300 and the Max. Length of Job is 635 mm. The technical details are as follows -

- Cutting Thickness

- Depends on tool and material; typically up to 20 mm

- Cutting Speed

- Variable, spindle speed range up to 2,500 rpm

- CNC Or Not

- Manual (Not CNC)

- Automatic Grade

- Manual

- Control System

- Manual control with lever-operated feed and thread cutting

- Max. Swing Diameter

- M300 model - 300 mm

- Voltage

- 415 V, 3-phase (standard for industrial lathe)

- Weight (kg)

- Approx. 800 kg

- Dimension (L*W*H)

- Approx. 1650 mm x 800 mm x 1980 mm

- Capacity

- Max. Length of Job: 635 mm

- Feature

- Sturdy construction, gap-bed, precision hardened and ground bed, rapid traverse

- Color

- Industrial Grey

- Feed Range

- Longitudinal and cross feed available

- Power Requirement

- Approx. 2 kW

- Coolant System

- Integrated coolant pump

- Tailstock Quill Travel

- 95 mm

- Distance Between Centers

- 635 mm

- Number of Spindle Speeds

- 12

- Lead Screw Thread

- Pitch 4 mm

- Safety Features

- Emergency stop, safety interlocks

- Thread Cutting Capability

- Metric and Imperial threads, various pitches

- Tailstock Quill Diameter

- 48 mm

- Spindle Bore

- 40 mm

- Spindle Nose

- DIN55027

- Chuck Type

- 3-jaw self-centering

- Bed Type

- Gap-Bed

About Harrison England M300 x 635 mm Length Gap-Bed Lathe Machine

Sturdy Gap-Bed Construction for Precision Machining

The M300's gap-bed design ensures high rigidity while accommodating larger workpieces. The bed is precision-hardened and ground, providing a smooth and accurate foundation for all turning operations. This makes the machine suitable for various industrial tasks requiring strict tolerances and reliable performance.

Versatile Manual Control System

Engineered for hands-on operation, the M300 offers manual lever-controlled feeding and threading. It supports both longitudinal and cross feed, as well as thread cutting for metric and imperial pitches. This versatility suits a broad range of applications in metalworking, repair, and production environments.

Integrated Coolant System and Enhanced Safety

With an integrated coolant pump and robust safety features, including an emergency stop button and safety interlocks, the M300 promotes user safety and extends tool life. These features ensure the lathe is suitable for continuous industrial use while minimizing risks and downtime.

FAQ's of Harrison England M300 x 635 mm Length Gap-Bed Lathe Machine:

Q: How do I operate the Harrison M300 lathe for thread cutting?

A: The M300 lathe offers manual lever control for engaging feed and thread-cutting mechanisms. To cut threads, select the desired pitch (metric or imperial), adjust the feed rate, and engage the threading lever as per the operation manual. Always ensure safety interlocks are active before starting.Q: What is the maximum size workpiece the M300 can handle?

A: The M300 can accommodate a maximum swing diameter of 300 mm and supports a job length of up to 635 mm between centers. The gap-bed feature allows handling slightly larger diameters near the headstock.Q: When should I use the integrated coolant system?

A: Activate the coolant pump during prolonged or heavy-duty machining to reduce heat buildup, improve cutting performance, and increase tool longevity. The integrated system can be switched on as needed using the control panel.Q: Where is the M300 commonly used?

A: This lathe is widely employed in industrial workshops, repair shops, manufacturing plants, and by exporters, importers, and suppliers dealing with metalworking operations due to its reliability and versatility.Q: What safety precautions are in place on the M300 lathe?

A: The M300 is equipped with multiple safety features, including an emergency stop button and safety interlocks to prevent accidental startup during maintenance or setup, ensuring operator safety at all times.Q: How does the gap-bed design benefit my machining process?

A: The gap-bed design allows operators to machine workpieces with larger diameters near the headstock by temporarily removing a section of the bed, offering increased flexibility without compromising structural integrity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lathe Machine Category

Colchester England 2000 mm Length Gap-Bed Lathe Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : 2000 mm between centers

Feature : Other, Heavyduty construction, precision spindle, removable gap

Max. Swing Diameter : 540 mm over bed

Voltage : 415 V, 3 phase

TOS 3500 mm Heavy Duty Lathe Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : 3500 mm between centers

Feature : Other, High rigidity, durable construction, precision ground bed ways

Max. Swing Diameter : 800 mm

Voltage : 415 V, 3 Phase, 50 Hz

Colchester Master 2500 Lathe Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : Medium Duty, General Engineering

Feature : Other, Induction Hardened Bedways, Hardened and Ground Gears, High Accuracy

Max. Swing Diameter : 360 mm over bed

Voltage : 415 V, 3 Phase

TOS SU-80A 3500 mm Heavy Duty Lathe Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : Heavy Duty Turning

Feature : Other, Robust Construction, Precision Performance

Max. Swing Diameter : 800 mm

Voltage : 415 V

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry