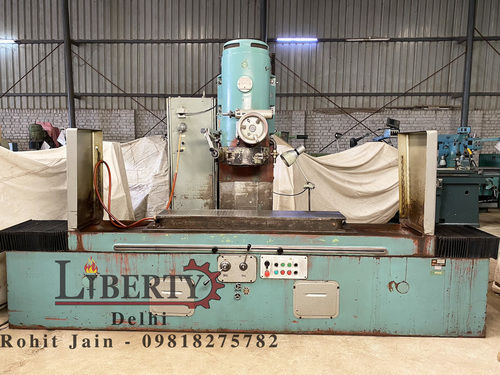

Kent Taiwan 300 mm x 600 mm CNC Surface Grinding Machine

Price 100000 INR/ Piece

Kent Taiwan 300 mm x 600 mm CNC Surface Grinding Machine Specification

- Model

- KGS-3060CNC

- Rotation

- Clockwise

- Product Type

- Surface Grinding Machine

- General Use

- Precision CNC Surface Grinding

- Material

- Heavy Duty Cast Iron

- Type

- CNC Surface Grinder

- Capacity

- 600 mm Grinding Length

- Weight (kg)

- 2500 kg

- Computerized

- Yes

- Automatic

- Yes

- CNC Or Not

- CNC

- Control System

- Fanuc / Mitsubishi

- Table Size

- 300 mm x 600 mm

- Table Slide Way

- Double V with Turcite-B lining

- Magnetic Chuck Size

- 300 mm x 600 mm

- Grinding Wheel Size

- 355 mm x 38 mm x 127 mm

- Grinding Wheel Speed

- 1450 rpm

- Grinding Length

- 600 mm

- Floor Space

- 2200 mm x 1800 mm x 1900 mm

- Fuel Tank Capacity

- 65 Liters

- Spindle Speed

- 1450 rpm

- Power

- 5 HP / 3.7 kW

- Voltage

- 380V / 415V

- Dimension (L*W*H)

- 2200 mm x 1800 mm x 1900 mm

- Feature

- High Precision, Rigid Structure, Easy Operation

- Color

- White & Blue

- Max Grinding Width

- 300 mm

- Column Vertical Travel

- 450 mm

- Spindle Motor

- 5 HP

- Rapid Feed Speed

- 200 mm/min (vertical)

- Accuracy (Flatness)

- 0.002/300 mm

- Minimum Increment (Feed)

- 0.001 mm

- Coolant Tank Capacity

- 80 L

- Control Panel

- Touch Screen Interface

- Lubrication

- Automatic Centralized

- WorkingSpeed

- 0.5~25 m/min

- Cross Feed Travel

- 340 mm

- Noise Level

- 76 dB(A)

- Hydraulic Oil Tank Capacity

- 65 L

- Application

- Tool Room, Die & Mould, Machine Building

- Table Longitudinal Travel

- 650 mm

Kent Taiwan 300 mm x 600 mm CNC Surface Grinding Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About Kent Taiwan 300 mm x 600 mm CNC Surface Grinding Machine

Make - Kent (Taiwan)

Model - KGS-63SD

Magnet Size - 300 mm x 600 mm

Grinding Wheel Size - Diameter 355 mm x 40 mm Width

Job Grinding Capacity - 300 mm x 650 mm

Longitudinal Travels - 710 mm

Cross Travels - 340 mm

Max. Height between Magnet Top to Wheel Center - 445 mm

Least Count - 1 Micron (0.001 mm)

CNC Controller - Fanuc Oi-MD

- Complete with Wheel Dressers, Wheel Balancing Stand, Wheel Flanges etc.

- Operating Manual, Electrical Drawings, other documentation is available.

- Complete with Magnetic type Coolant Filtration Unit, Coolant Tank and Pump.

- Machine is in excellent working condition.

Video of The Machine -

Precision Ground for Demanding Applications

Designed for general-purpose and precision applications, the Kent Taiwan 300 x 600 mm CNC Surface Grinder delivers remarkable flatness ( 0.002/300 mm) and excellent stability. Its robust build, paired with advanced CNC controls, makes it suitable for tool rooms, die and mould industries, as well as machine building tasks where consistency and accuracy are crucial.

User-Friendly and Efficient Operation

The machine combines touch screen convenience with CNC automation, streamlining setup and operation. Automatic centralized lubrication, rapid feed speeds, and hydraulic systems extend component life and optimize performance. Easy adjustment via the intuitive control panel ensures operators can achieve precise results with minimal effort.

FAQ's of Kent Taiwan 300 mm x 600 mm CNC Surface Grinding Machine:

Q: How does the Kent Taiwan CNC Surface Grinding Machine achieve high precision?

A: The machine leverages CNC control (Fanuc/Mitsubishi), double V slide-ways with Turcite-B lining, and robust construction to ensure flatness accuracy of 0.002/300 mm. Automatic lubrication and a stable cast iron body further reduce vibration and wear, promoting consistent high-precision grinding.Q: What types of applications is this surface grinder best suited for?

A: This CNC surface grinder is ideal for tool rooms, die & mould making, and machine building. Its precision and programmable functions make it suitable for demanding general-purpose grinding and finishing tasks that require repeatable accuracy.Q: When should you use CNC over manual surface grinders?

A: CNC surface grinders like the KGS-3060CNC should be used when you require high repeatability, multiple step grinding, or complex shapes. CNC automation reduces human error, enhances productivity, and is essential for batch production or precision work.Q: Where can this machine be installed and operated efficiently?

A: The KGS-3060CNC fits well in industrial environments, such as manufacturing workshops, tool rooms, and specialized production lines. With floor dimensions of 2200 mm x 1800 mm x 1900 mm and low noise levels, it integrates easily into modern facilities focused on quality surface finishing.Q: What is the process for setting up and operating the machine?

A: Operation involves securing the workpiece on the magnetic chuck, selecting parameters via the touch screen interface, and programming the grinding cycle as required. The automatic systems manage lubrication and feed operations, while the user monitors efficiency and results through the control panel.Q: What are the key benefits of using this CNC surface grinder?

A: Key benefits include superior grinding accuracy, user-friendly CNC programming, automatic lubrication, durable construction, and low noise levels. Its combination of performance and convenience reduces downtime, increases productivity, and ensures high-quality surface finishes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Surface Grinder Category

Ernault Somua 220 mm x 650 mm Surface Grinder Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : Other, No, manual

Computerized : No

CNC Or Not : Other, Not CNC

Feature : Other, High precision, heavyduty construction, magnetic chuck included

MAS BPV 300 x 1500 Vertical Surface Grinder

Price 33000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : No

Computerized : No

CNC Or Not : Other, Not CNC (Conventional)

Feature : Other, High Precision Finish, Sturdy Construction

Alpa Italy 300 x 600 Surface Grinding Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : No

Computerized : No

CNC Or Not : Other, No

Feature : Other, High rigidity, Precise finishing

Favretto 310 x 1150 Surface Grinding Machine

Automatic : Other, Semiautomatic

Computerized : No

CNC Or Not : Not CNC, Other

Feature : Surface grinding for precision applications, Other

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry