Voumard type 5A Internal Grinding Machine

Voumard type 5A Internal Grinding Machine Specification

- Rotation

- Workhead rotation: up to 1,100 rpm

- Model

- Voumard Type 5A

- Product Type

- Internal Grinding Machine

- General Use

- Internal cylindrical grinding of workpieces

- Material

- Cast iron body, steel components

- Type

- Voumard Type 5A

- Capacity

- Workpiece diameter up to 250 mm

- Weight (kg)

- Approx. 1800 kg

- Computerized

- No

- Automatic

- No

- CNC Or Not

- No (Conventional/Manual)

- Control System

- Hand-operated with mechanical controls

- Table Size

- 700 x 165 mm

- Table Slide Way

- Box type, precision ground

- Magnetic Chuck Size

- 200 mm

- Grinding Wheel Size

- 300 x 42 x 127 mm

- Grinding Wheel Speed

- Up to 21,000 rpm

- Grinding Length

- 120 mm

- Floor Space

- Approx. 1600 x 1400 mm

- Spindle Speed

- Up to 28,000 rpm (internal grinding spindle)

- Power

- 2.5 kW main motor

- Voltage

- 380 V, 3 phase

- Dimension (L*W*H)

- Approx. 1600 x 1400 x 1800 mm

- Feature

- High precision for bore grinding, internal surface finishing

- Color

- Standard factory grey/green

- Wheelhead Swivel

- ±15°

- Lubrication

- Centralized automatic lubrication

- Electrical System

- Standard industrial electricals, 50 Hz

- Cross Feed Travel

- 90 mm

- Workhead Taper

- Morse Taper No. 4

- Max Workpiece Swing

- 250 mm

- Coolant System

- Integrated coolant pump

- Max Workpiece Length

- 150 mm

- Working Speed

- Variable, hand controlled

- Surface Finish

- Up to Ra 0.2 µm (with suitable wheel and setup)

- Max Internal Grinding Depth

- 120 mm

About Voumard type 5A Internal Grinding Machine

Make - Voumard (Switzerland)

Model - 5A

Grinding Diameter - 5 mm to 200 mm

Center Height - 180 mm

Max. Swing Diameter of Job - 360 mm

Grinding Depth - 250 mm

Maximum Table Stroke - 600 mm

Spindle Speeds - 3,600 rpm to 40,000 rpm

Work-Head Speeds - 125 rpm to 1,000 rpm

Work-Head Swivel - 0 Degree to 90 Degree

- Equipped with Face Grinding Attachment.

- Equipped with a Hydraulic Wheel-Dresser.

- Working in Auto Cycle.

- Operating Manual & Electrical Drawings available.

- Machine is in excellent working condition.

Video Link - https://youtu.be/CaaocsjOt5E

High Precision Internal Grinding

The Voumard Type 5A excels in delivering exceptional accuracy for internal cylindrical grinding applications. Its design combines robust materials and advanced mechanical control, ensuring reliable performance for producing fine surface finishes and precise bores in workpieces up to 250 mm in diameter. The integrated coolant and lubrication systems further enhance process stability and grinding consistency.

Versatile & Operator-Friendly Design

Built for manual operation, this machine features hand-controlled mechanical systems that allow skilled machinists to finely tune grinding operations. The cross feed travel of 90 mm and wheelhead swivel of 15 facilitate flexibility and adaptability when working on complex or irregular components. No CNC is required, making it accessible to operators familiar with conventional equipment.

FAQs of Voumard type 5A Internal Grinding Machine:

Q: How does the Voumard Type 5A achieve high levels of surface finish during internal grinding?

A: The machine offers precise control through manual adjustments, a robust spindle capable of up to 28,000 rpm, and an integrated coolant system that maintains optimal temperatures. With suitable grinding wheels and careful setup, it can achieve surface finishes as fine as Ra 0.2 m.Q: What type of workpieces can be ground using this machine?

A: This model is ideal for the internal cylindrical grinding of workpieces with a maximum swing diameter of 250 mm and length up to 150 mmcommonly found in automotive, aerospace, and general machining industries requiring precision bores and smooth internal surfaces.Q: When should I use the Voumard Type 5A over a CNC grinding machine?

A: Choose this machine when you require precise, hands-on control for unique or small batch parts, or where flexibility and manual intervention are valuable. Its particularly suitable when CNC automation is unnecessary or when skilled operators are available for intricate adjustments.Q: Where is the Voumard Type 5A typically installed and used?

A: It is commonly installed in precision machining workshops, tool rooms, and manufacturing plants, especially those dealing with high-accuracy internal grinding. Its moderate footprint (approx. 1600 x 1400 mm) fits standard industrial shop floors.Q: What is the process for operating the machine for internal grinding tasks?

A: Operation involves securely mounting the workpiece, selecting the appropriate wheel, setting the workhead rotation, adjusting the feed and swivel angles, and using the hand-operated controls to begin grinding. The centralized automatic lubrication and built-in coolant systems simplify maintenance during operation.Q: How does the built-in coolant and lubrication system benefit users?

A: These systems maintain optimal grinding conditions by controlling heat and reducing friction throughout the process. This extends tool life, ensures dimensional stability, and contributes to a consistent, fine surface finish on the workpiece.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Internal Grinding Machine Category

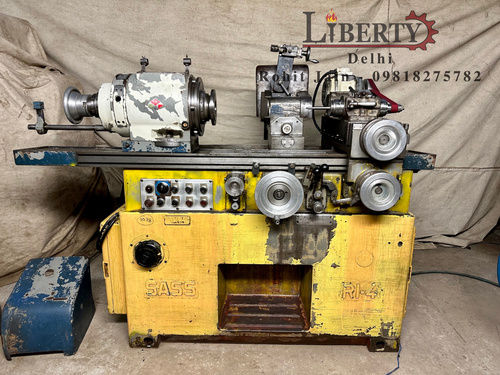

SASS Italy RI-4 Internal Grinder Machine

Price 25000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 415V / 3 Phase

Feature : Other, High accuracy, rigid construction, easy operation

Control System : Other, Handoperated/mechanical

Power : 1.1 kW

Fortuna Internal Grinding Machine

Price 50000 INR

Minimum Order Quantity : 1 Piece

Voltage : 415 V

Feature : Other, High precision grinding, durable structure

Control System : Manual

Power : 2 HP

Voumard Type 5A Internal Grinding Machine

Price 60000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 415 V, 3 Phase, 50 Hz

Feature : Other, High accuracy, smooth operation, robust construction

Control System : Other, Conventional manual controls

Power : 3.7 kW (5 HP)

Fortuna Internal Grinding Machine

Price 5000 USD ($)

Minimum Order Quantity : 1 Piece

Voltage : 415 V, 3 Phase

Feature : Other, High precision, robust construction, smooth operation

Control System : Manual

Power : 2 HP

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry