TOS Czech ST-350 Vertical Slotting Machine

Price 100000.0 INR/ Piece

TOS Czech ST-350 Vertical Slotting Machine Specification

- Model No

- ST-350

- Noise Level

- < 75 dB

- Features

- Adjustable stroke, robust cast iron frame, high precision

- Voltage

- 380 V

- Production Capacity

- 1 Unit/Hour

- Lubricating System

- Automatic lubrication

- Power Rating

- 3.5 kW

- Frequency

- 50 Hz

- Operating Temperature

- 0C - 40C

- Cooling System

- Integrated coolant system

- Machine Type

- Slotting Machine

- Motor Power

- 3.5 kW

- Accuracy

- 0.015 mm

- Control System

- Conventional / Manual

- Drive

- Electric Motor

- Frame Type

- Rigid cast iron

- Product Type

- Vertical Slotting Machine

- Technology

- Slotting

- Power Source

- Electric

- Operating Type

- Automatic/Manual

- Power

- 3.5 kW

- Pressure

- 0.5 - 2 MPa

- Surface Treatment

- Painted

- Dimension (L*W*H)

- 1850 x 1350 x 2450 mm

- Weight (kg)

- 1950 kg

- Color

- Light Blue / Cream

- Usage & Applications

- Manufacturing, Metalworking, Grooving, Industrial Slotting

- Tool Holding Shank

- 32 mm

- Maximum Table Load

- 800 kg

- Table Traverse (X/Y)

- 315/375 mm

- Main Material

- High-grade cast iron and steel

- Ram Stroke Length

- 350 mm

- Maintenance

- Low, with centralized lubrication

- Slotting Capacity (Steel)

- Up to 10 mm thickness

- Main Shaft Speed

- Variable, up to 112 strokes/min

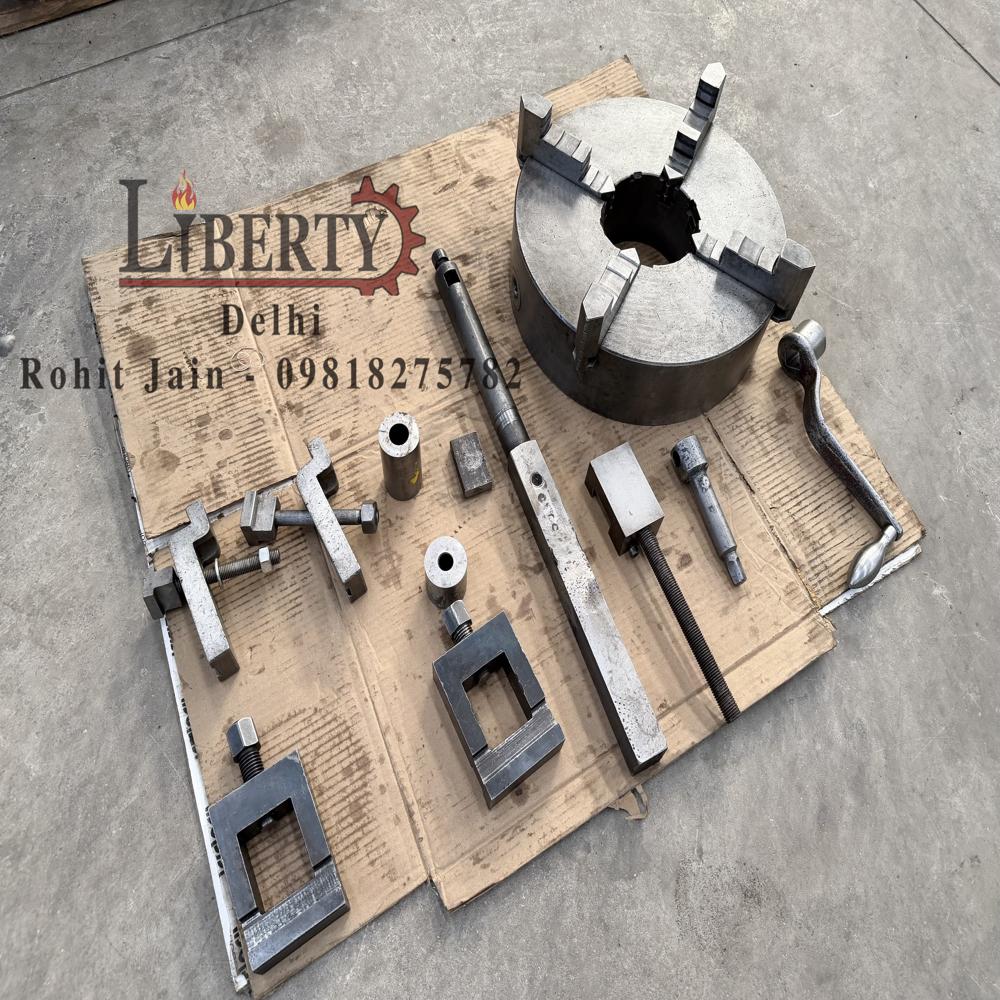

- Standard Accessories

- Tool holder, coolant pump, operation manual

- Installation

- Floor mounted

- Maximum Slotting Height

- 350 mm

- Table Rotation

- 360°

- Slotting Angle Adjustment

- ±60°

- Safety Features

- Overload protection, emergency stop

- Table Diameter

- 500 mm

About TOS Czech ST-350 Vertical Slotting Machine

Engineered Precision and Performance

The TOS Czech ST-350 boasts advanced slotting capabilities, featuring a rigid cast iron frame for unmatched stability and a maximum slotting height of 350 mm. Its 500 mm diameter table facilitates 360 rotation, enabling versatile part positioning and operation. Variable ram stroke speeds up to 112 strokes per minute ensure efficiency, while the high-grade steel construction maintains precision throughout prolonged use.

Robust Construction and User-Friendly Operation

Constructed from high-grade cast iron and steel, the ST-350 stands up to rigorous industrial demands, achieving a slotting capacity of up to 10 mm in steel. The electric motor-driven machine supports both automatic and manual control, catering to operator preferences and task requirements. Thoughtful features include adjustable ram stroke, overload protection, and an emergency stop to enhance operator safety.

Effortless Maintenance and Reliable Cooling

Maintenance is streamlined through a low-maintenance, centralized automatic lubrication system and an integrated coolant pump, maximizing machine service life. The painted surface treatment offers additional durability for challenging environments. Noise levels remain below 75 dB, promoting a comfortable workshop atmosphere, while the machine operates efficiently between 0C and 40C.

FAQ's of TOS Czech ST-350 Vertical Slotting Machine:

Q: How do I operate the TOS Czech ST-350 in both automatic and manual modes?

A: The ST-350 can be operated using its manual controls for precision tasks or switched to automatic mode for repetitive slotting cycles. Detailed instructions are provided in the operation manual included with the machine.Q: What applications is the ST-350 Vertical Slotting Machine best suited for?

A: This machine excels in manufacturing, metalworking, grooving, and industrial slotting tasks, especially where high precision and handling of heavy components, up to 800 kg, are required.Q: When should maintenance be performed on the ST-350, and how is it simplified?

A: Thanks to its centralized automatic lubrication system, regular user maintenance needs are minimal. Periodic checks of the lubricating and cooling systems as outlined in the manual will ensure consistent performance and reliability.Q: Where should the ST-350 be installed for optimal performance?

A: Install this machine on a solid, level floor in a well-ventilated workshop environment, ensuring easy access to an appropriate 380 V, 50 Hz electric power supply and adherence to the indicated temperature range (0C - 40C).Q: What is the process for slotting steel using the ST-350, and what are its capacity limits?

A: To slot steel, secure the workpiece on the table, select the desired ram stroke and speed, and engage the slotting process via the control system. The machine accommodates steel up to 10 mm thick with a slotting accuracy of 0.015 mm.Q: What benefits does the integrated coolant system provide during operation?

A: The integrated coolant pump ensures efficient cooling during heavy-duty slotting, reducing heat buildup, prolonging tool life, and maintaining high quality in finished components.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Slotting Machine Category

TOS HOV-45 Heavy Duty Slotting Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Surface Treatment : Other, Painted/Coated

Color : Industrial Green

Frame Type : Rigid column with bed frame

Usage & Applications : Slotting/internal cutting of metals and components

TOS HOV40 Heavy Duty Slotting Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Surface Treatment : Other, Coated/Painted

Color : Machine Grey

Frame Type : Heavy Cast Iron

Usage & Applications : Metal Slotting, Keyway cutting, Internal Gear Cutting, Shaping Operations

Butler 12 inch Precision Toolroom Slotter Machine

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Surface Treatment : Painted

Color : Industrial Green / Grey

Frame Type : Box type, heavy duty

Usage & Applications : Precision slotting, keyway cutting, toolroom and general engineering applications

Ramira 320 mm Vertical Slotting Machine

Price 40000 INR / Piece

Minimum Order Quantity : 1 Piece

Surface Treatment : Other, Painted / Coated

Color : Green

Frame Type : Heavy Duty Cast Iron

Usage & Applications : Slotting and keyway operations on metal, tools, dies

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry