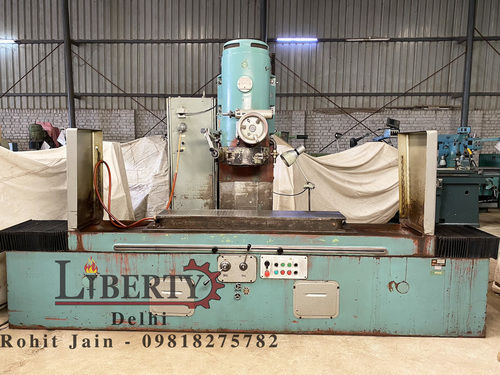

ZVL TOS BRH-20A Surface Grinding Machine

Price 100000 INR/ Piece

ZVL TOS BRH-20A Surface Grinding Machine Specification

- Rotation

- Clockwise

- Model

- BRH-20A

- Product Type

- Surface Grinding Machine

- General Use

- Industrial Surface Grinding

- Material

- Cast Iron

- Type

- Horizontal Spindle

- Capacity

- Standard

- Weight (kg)

- Approx. 1450 kg

- Computerized

- No

- Automatic

- No

- CNC Or Not

- Not CNC

- Control System

- Manual

- Table Size

- 500 x 200 mm

- Table Slide Way

- V-flat guideways

- Magnetic Chuck Size

- 500 x 200 mm

- Grinding Wheel Size

- 200 x 13 x 32 mm

- Grinding Wheel Speed

- 2800 RPM

- Grinding Length

- 500 mm

- Floor Space

- 1750 x 1200 mm

- Fuel Tank Capacity

- Approx. 50 Litres

- Spindle Speed

- 2800 RPM

- Power

- 2 HP

- Voltage

- 415 V, 3 Phase

- Dimension (L*W*H)

- 1750 x 1200 x 1600 mm

- Feature

- High Precision, Rigid Construction

- Color

- Blue / White

- Surface Finish

- 0.5 m Ra

- Packing Case Dimension

- Approx. 2000 x 1300 x 1900 mm

- Vertical Feed Graduation

- 0.005 mm

- Lubrication System

- Automatic Centralized

- Manual Feed per Handwheel Revolution

- 5 mm

- Cross Feed Graduation

- 0.02 mm

- Spindle Motor Power

- 2 HP / 1.5 kW

- Max Distance from Table Surface to Spindle Center

- 370 mm

- WorkingSpeed

- Variable, Manual Feed

- Coolant Pump Power

- 40 W

- Table Longitudinal Travel

- 540 mm

ZVL TOS BRH-20A Surface Grinding Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About ZVL TOS BRH-20A Surface Grinding Machine

Make - ZVL TOS (Czech Republic)

Model - BRH-20A

Magnet Size - 200 mm x 630 mm

Grinding Wheel Size - Diameter 250 mm x 25 mm Width

Max. Longitudinal Travels - 700 mm

Max. Cross Travels - 230 mm

Max. Height between Wheel-Center & Magnet Top - 365 mm

Least Count of Vertical Travel - 2 Microns (0.002 mm)

- Feature of Automatic Depth Adjustment and Plunge Grinding.

- Complete with Coolant Tank and Coolant Pump.

- Complete with many spare Grinding Wheels, Flange, etc.

- Complete with Wheel Balancing Stand, and many other accessories.

- Operating Manual & Electrical Drawings are available.

- Machine is in excellent working condition.

Video of the Machine -

High Precision and Rigid Structure

The BRH-20A is engineered for accuracy and strength, utilizing cast-iron construction and V-flat guideways for exceptional stability and low wear. These features enable fine surface finishes and consistent results, meeting the demanding standards of industrial grinding applications.

User-Friendly and Manual Operation

With intuitive manual controls-including fine graduations for cross and vertical feed-the machine allows for precise adjustments. Operators benefit from straightforward setup and easy handling, ideal for industrial workshops seeking reliable performance without the complexity of CNC systems.

Efficient Lubrication and Cooling System

Automatic centralized lubrication and a powerful coolant pump help maintain smooth operation and enhance machine longevity. This ensures reduced maintenance needs and optimal performance even in high-use manufacturing environments.

FAQ's of ZVL TOS BRH-20A Surface Grinding Machine:

Q: How does the ZVL TOS BRH-20A ensure precise surface grinding results?

A: The BRH-20A features highly accurate manual feed graduations (0.02 mm cross, 0.005 mm vertical) and robust V-flat guideways. Its rigid cast-iron build and high-speed spindle further contribute to achieving precise surface finishes as fine as 0.5 m Ra.Q: What materials and workpiece sizes can the BRH-20A handle?

A: This machine is suitable for grinding various metals and is constructed to accommodate workpieces up to 500 x 200 mm on its magnetic chuck. The maximum distance from table surface to spindle center is 370 mm, making it versatile for many industrial tasks.Q: When should the centralized lubrication system be serviced?

A: While the machine's automatic centralized lubrication minimizes manual maintenance, it's advised to check lubricant levels regularly (e.g., weekly or after heavy use) and refill the approx. 50-litre tank as needed to ensure optimal performance.Q: Where is the BRH-20A most commonly used?

A: This model is designed for industrial environments, including manufacturing workshops, tool rooms, and facilities in sectors requiring high-precision surface grinding. Its durability and reliability make it suitable for exporters, importers, and suppliers alike.Q: What is the process for adjusting grinding speed and feed rates?

A: Operators can adjust working speed and manual feed via control handwheels. Step graduations allow precise table and wheel positioning for different material requirements, and the variable speed ensures adaptability to specific grinding tasks.Q: What benefits does the BRH-20A offer over CNC grinders?

A: While it is manual and not CNC, the BRH-20A offers simplicity, lower maintenance, and cost-effectiveness. Its manual control and high precision are ideal for applications where nuanced operator input and flexibility are paramount.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Surface Grinder Category

Taiwan 355 mm x 710 mm Surface Grinding Machine

Price 15000 INR / Piece

Minimum Order Quantity : 1 Piece

Fuel Tank Capacity : 90 liters

Type : Other, Manual Surface Grinder

Grinding Wheel Speed : 1450 RPM

Computerized : No

MAS BPV 300 x 1500 Vertical Surface Grinder

Price 33000 INR / Piece

Minimum Order Quantity : 1 Piece

Fuel Tank Capacity : 50 Litres (Hydraulic oil reservoir)

Type : Surface Grinding Machine

Grinding Wheel Speed : 1450 RPM

Computerized : No

Alpa 200 mm x 450 mm Surface Grinding Machine

Price 45000 INR / Piece

Minimum Order Quantity : 1 Piece

Fuel Tank Capacity : 30 Liters (Hydraulic Tank)

Type : Other, Horizontal

Grinding Wheel Speed : 2800 RPM

Computerized : No

G. Rastelli RT-1 Surface Grinding Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Fuel Tank Capacity : Builtin Lubrication Tank

Type : Other, Manual

Grinding Wheel Speed : 2800 RPM

Computerized : No

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry